Developments in Top of Rail and Gage Face Friction Management Consumables

by Jeff Tuzik

Friction management works. Whether at the gage face or top of rail, the benefits are widely known and widely quantified. Friction management products facilitate reduced rail wheel wear, RCF mitigation, noise reduction, improved fuel efficiency, and many other systemic benefits. Although these benefits are considered settled science, advancements in friction management consumables continue to adjust the way these products are employed, and the value proposition they present.

Top of rail (TOR) friction modification (FM) products are designed to hit a target coefficient of friction usually in the 0.30 to 0.4 range – a balance between wear reduction/RCF mitigation and traction; “any lower than 0.30 would have a deleterious effect on wheel traction and braking,” Louisa Stanlake, L.B. Foster Technologies’ Global Product Manager – Consumable products, told delegates at the 2022 Wheel/Rail Interaction conference.

TOR consumables fit into one of three broad categories based on their composition. There are water, oil, and hybrid water/oil products with different characteristics and applications. Water-based FM products differ from the other two types in that they evaporate, leaving a dry film with an intermediate target-friction-level. Hybrid and oil-based products are non-drying and tend to target lower friction levels. “Oil-based consumables can achieve an intermediate friction level, but it requires fine-tuning the application rate in order to avoid over-lubricating,” she said.

FM value/cost is determined by the total cost of ownership, which includes annual product consumption, product re-filling, seasonal product switch-out (winter vs summer), track access, product storage, and applicator maintenance. Advancements in all-season, higher-performance, and more environmentally friendly consumables have also affected the total cost of ownership.

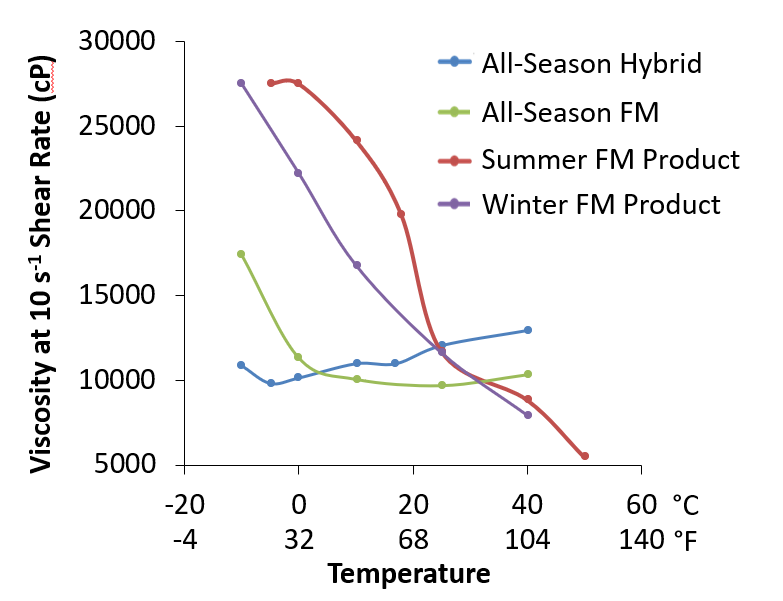

Traditional seasonal TOR and GF consumables are designed around and constrained by their operating temperatures which generally range from -40 to 122 degrees Fahrenheit (-40 to 50 C). And because seasonal consumables are specifically designed around one extreme or the other, performance in the shoulder seasons can suffer. These modern all-season consumables are truly viable in all operating temperatures and have been proven in field applications. Very low temperatures raise the viscosity of the consumable and can render applicator pumps unable to apply it adequately. High temperatures on the other hand lower viscosity and adhesion, often causing the consumable to be over-applied, leading to significant waste. “Rail gets very hot in the summer, and if they’re hot enough that the consumable can’t adhere to the rail surface, it’s not going to provide any benefit,” Stanlake said. The current generation of all-season consumables have been engineered to be more consistent at a range of temperatures; they have increased carry-down and adhesion properties, more consistent application/output rate, and better stability in storage.

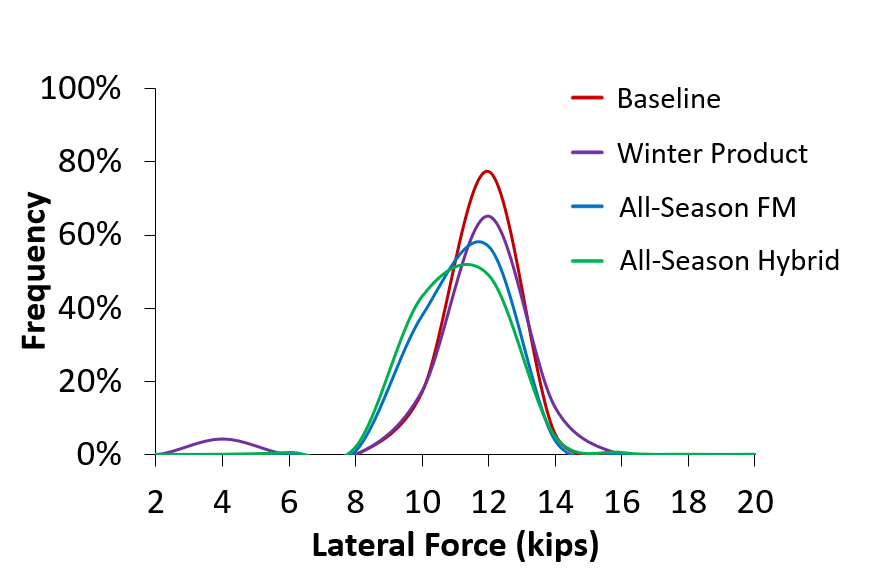

In order to ensure that consumables perform properly at a range of temperatures, manufacturers like L.B. Foster conduct various laboratory, scale, and field tests. And while laboratory testing is a critical part of development, field-testing is typically considered the gold-standard for demonstrating the real-world performance of the consumables. L.B. Foster conducted field tests on three of their TOR products — an all-season water-based, an all-season hybrid, and a cold-weather water-based friction modifier — on an 8-degree curve with an ambient temperature range of 50 to -14 degrees Fahrenheit, with an average of 17 F degrees ( 10 to -25 degrees C, with an average of 8 degrees C) . The applicator unit was positioned at the beginning of the curve (before the spiral) in tangent track and a lateral/vertical (L/V) force measurement device was installed 3.5 miles down the track.

For the baseline (no TOR applied) measurement, the majority of the wheels passing through the L/V monitor measured between 10.5 to 14 kips (averaging about 12 kips). The results of the cold-weather TOR test were nearly identical (see figure 3). However, both all-season consumables showed substantial improvement, with L/V measurements averaging 11 kips. Despite being formulated for cold-weather operation, the cold-weather consumable’s higher viscosity and film durability meant that it’s carry-down rate couldn’t match that of the all-season formulations, Stanlake said.

All-season TOR FM has now been implemented in a number of locations with widely varying temperature ranges. Data collected over multiple years of use in these locations has validated L.B. Foster’s laboratory results indicating that all-weather consumables are on average more effective and efficient than their seasonal counterparts. “The better carry-down rates of high-performance all-season [consumables] mean less product is consumed, leading to an overall lower total cost of ownership,” she said.

As wayside consumables have evolved, so too have on-board friction management products. Wayside and on-board TOR FM are used to achieve the same, generally equivalent, result — lower L/V forces, reduced wear, and optimized adhesion. But due to the difference in their application method, there are differences in their formulation. Wayside TOR product is significantly more viscous than on-board FM. Where wayside applicators apply beads of product, on-board units produce a fine, atomized spray, Stanlake said.

“On-board TOR consumables are [generally] water-based, so they’re sensitive to temperature, particularly low temperatures,” she said. As a result, on-board applicators typically require a significant amount of energy to heat not just the consumable, but also the hoses and nozzles of the applicator. “This introduces significant complexity (and cost) to the system, and significant unplanned maintenance,” she added. And even with properly functioning heating systems, there is still variability in the output rate of the consumable, depending on temperature.

In the case of on-board TOR, all-season consumables eliminate the necessity of the heating system and enable a more consistent output rate across a wider range of temperatures, Stanlake said. In L.B. Foster’s twin-disc testing comparing their original, seasonal on-board product with their newly-developed all-season product, the latter achieved twice the retentivity or carry-down rate. “[This] combination of reducing the complexity of the applicator and increasing the efficiency of the consumable nets a significant reduction to total cost of ownership.”

Gage Face Lubrication

Gage face (GF) lubricants (greases) aim to drive the coefficient of friction as low as possible, typically 0.25 or lower (0.30 for gage corner); “any friction levels above 0.30 on the gage corner and you begin to see metal filings due to gage wear,” Stanlake said. Like TOR consumables GF grease is formulated in seasonal and all-season variants. And as with TOR, the aim is to achieve a consistent viscosity across the full range of operating temperatures.

Unlike TOR consumables, grease is always oil-based. Its viscosity is measured by penetration-testing (a cone is dropped into a volume of grease and its depth of penetration recorded) and graded on the NLGI (National Lubricating Grease Institute) scale. Summer-formulated greases, which are harder, are typically NLGI grade 2, while softer winter greases are grade 1. All-season greases tend between 1 and 1.5, she said. In addition to these metrics, greases are graded by their biodegradability. Older petroleum-based greases rank poorly in this category, as their degradation can take years. The synthetic oils used in newer all-season greases rank better here, degrading significantly faster and more completely.

To function properly, GF grease must meet a number of performance criteria in extreme temperatures in order to function properly:

- Adherence to hot or cold wheels and rail

- Low propensity for applicator bar clogging

- High pumpability

- Consistent output

- Low oil separation

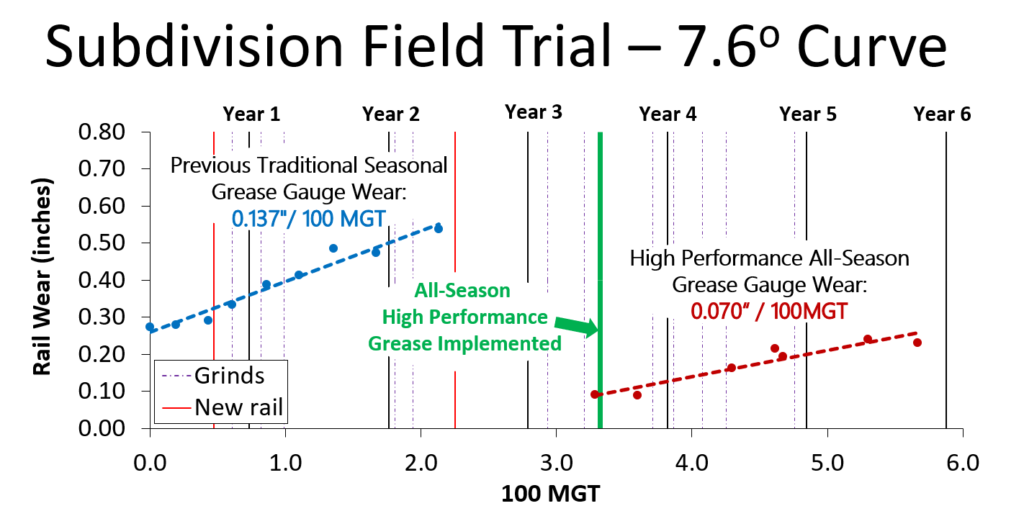

In order to assess the performance metrics of their all-season GF grease, L.B. Foster conducted a multi-year field test on a subdivision that was historically treated with seasonal GF grease. The site featured 20 curves and 25 wayside applicators. Based on prior twin-disc tests that indicated the all-season grease had significantly better carry-down than the seasonal variants, L.B. Foster deployed the all-season grease at a 50% reduced volume for the test, Stanlake said.

The test compared roughly two years of historical gage-face wear data to a similar time-frame after the introduction of the all-season grease. Under the previous grease regime, one 7.6-degree curve experienced 0.137 in. per 100 MGT gage-face wear. That same curve, treated with the all-season grease (at a 50% application rate) experience 0.070 in. per 100 MGT gage-face wear. While there may be other variables at play, such as ongoing rail grinding during the course of the study, they were kept consistent as possible throughout the trial. Regardless, the performance of the all-season grease appears to be self-evident. “The combination of less wear, less product consumption and reduced track accesses will drive a lower [total cost of ownership] over time,” Stanlake said.

Whether at the top of rail or gage face, the shift away from seasonal consumables appears to be a quantifiable benefit. And if these modern, all-season consumables can be applied at a reduced rate and still increase performance, as the data seems to indicate, the cost/benefit should be straight-forward. As more properties implement all-season consumables, it will be interesting to see how their experience compares to the results of studies like these.

Jeff Tuzik is Managing Editor of Interface Journal

This article is based on a presentation made at Wheel/Rail Seminars’ 2022 Wheel/Rail Interaction conference.

Images are courtesy of L.B. Foster.