Digging Into Cause Codes for Track-Related Derailments

by Jeff Tuzik

Derailments have many causes. Some are fairly simple and straightforward, others involve a complex combination of factors and circumstances. Determining the root causes is what keeps derailment investigators busy, and what helps railroads avoid such derailments in the future.

Over the years, and over the course of many derailments both major and minor, certain trends emerge, Gary Wolf, President of Wolf Railway Consulting—and one of North America’s preeminent derailment investigators—told attendees at the 2024 Wheel/Rail Interaction Heavy Haul Conference.

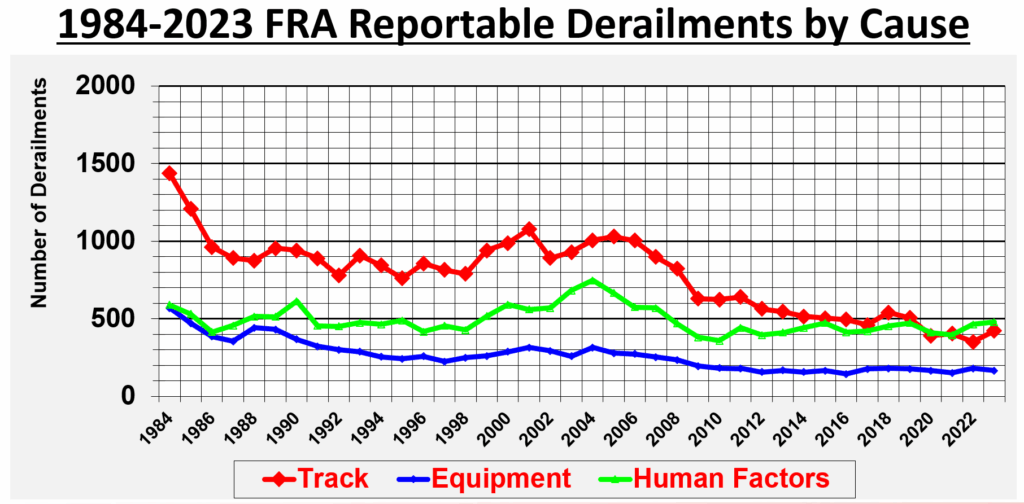

“The good news,” Wolf said, “is that back in 1984 we had about 1500 track-caused derailments in the US. In 2023, we were under 500.” This downward progression has generally been steady over the past 40 years. Mechanical-caused derailments have also decreased over this period, although the decrease has been less dramatic. Human factor-caused derailments, on the other hand, have remained nearly unchanged (see figure 1). “For the first time [since tracking this data] track-caused derailments account for fewer than human factor derailments,” he said.

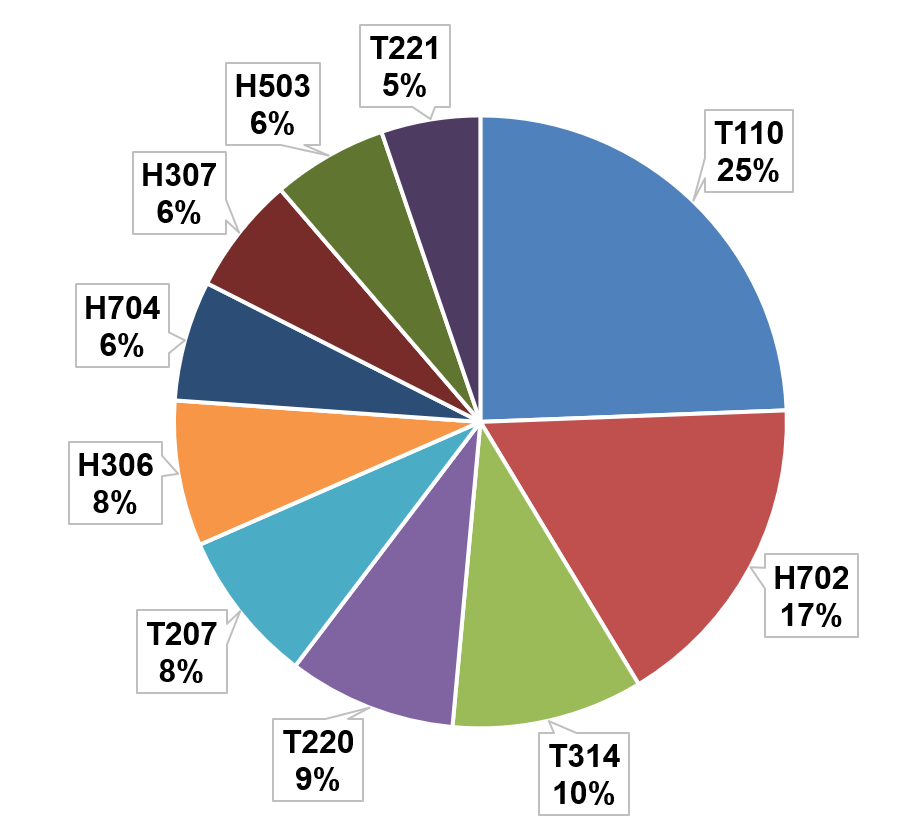

Figure 2 shows derailment data from the Federal Rail Administration (FRA) highlighting the top 10 derailment causes between 2000 and 2023. The leading cause, accounting for 25% of these derailments, is cause code T110 (wide gage). Behind that, accounting for 17%, is H702 (switch improperly lined). Broken rail-related causes T207 (detail fracture), T220 (transverse defect), and T221 (vertical split head) make up 8%, 9%, and 7%, respectively, for a total of 24%.

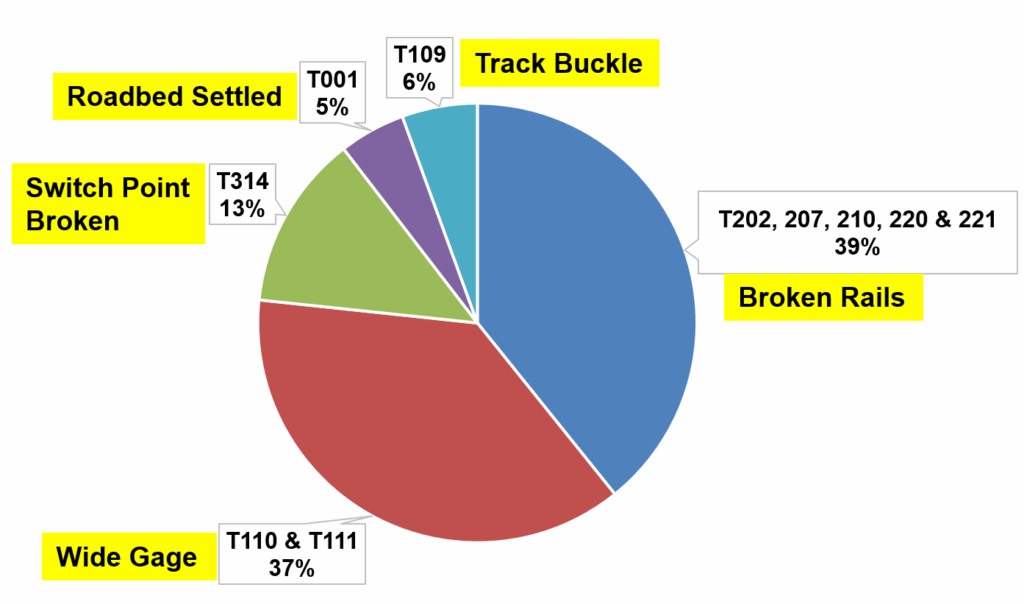

Focusing only on track-caused derailments over the same period (see figure 3), broken-rail-related causes make up a combined 39% of all (track-caused) derailments, Wolf said; wide gage is close behind at 37%. Broken switch points account for 13%, Soft of settled roadbed accounts for 5%, and track buckles account for 6%. “These are the big hitters of track-caused derailments; they make up 10,122 out of 16,247 derailments,” he said. Meaning, the top five causes of track-caused derailments comprise 62% of all track caused derailments.

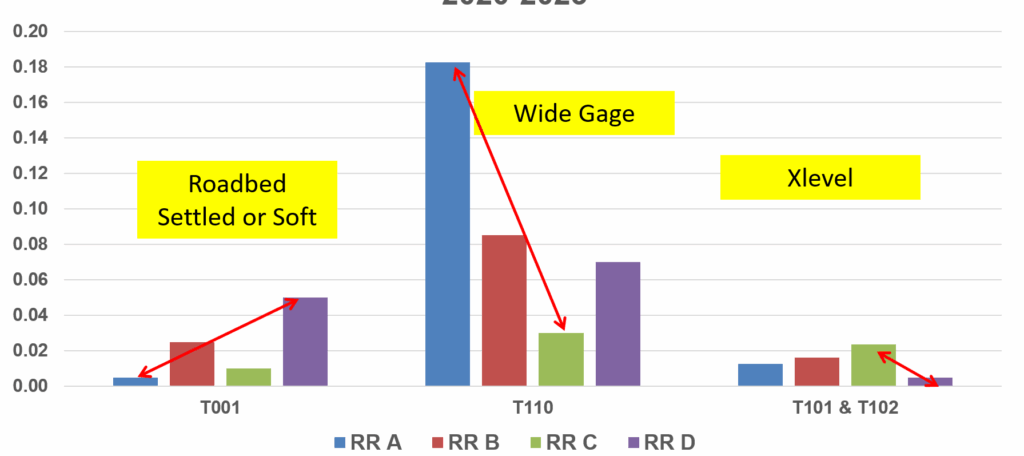

Interestingly, these derailment causes are not evenly distributed across the Class 1 railroads. In anonymized data on four Class 1s, for example, one railroad reported fewer than 0.01 derailments per million train miles with the cause code T001 (roadbed settled/soft), while another reported over 0.04 derailments per million train miles (see figure 4). “Keep in mind, you have to normalize these figures against the mileage of the individual railroads,” Wolf said. Nonetheless, this is a major disparity. Additionally, one railroad reported a high number of T001 derailments, but very few T101 and T102 (cross level-related) derailments. “This leads me to believe that maybe we’re not understanding exactly how to use these cause codes properly,” he said. Perhaps most strikingly, one railroad reported a very high number of wide-gage (T110) derailments (0.18 per million train miles), while another reported ≈0.02. “The top four Class 1s operate in a pretty similar fashion; these causes should be distributed fairly similarly.”

The cause code disparity indicates a general lack of accuracy and consistency in how railroads assign them, Wolf said. He also suggested that the FRA would do well to review and update cause codes for greater clarity and specificity, and perhaps develop a compliance manual detailing cause code assignation best practices. Railroads, he said, must develop uniform reporting practices for the sake of accuracy throughout the industry.

T110 – Wide Gage

T110 is the most-used cause code in the entire database, Wolf said, “But I think there’s a lot of misreporting here. A lot of wide-gage derailments are not due to track; they’re due to mechanical conditions, operational conditions, switching conditions [etc.], and yet we apply T110 because it’s simple and convenient. But you’ve got to do a deeper dive.”

The good news is that wide gage derailments (combining T110 and T111 [wide gage due to spikes/other rail fasteners]) are trending downward: from over 300 in 2000, to just under 100 in 2022, Wolf said. The industry-wide improvements that have contributed to this decrease primarily include:

- Greater focus on correction of excess rail cant

- Expanded use of concrete ties, which help with gage retention

- Larger tie plates, which help with load distribution

- Elastic fasteners

- Geometry cars with gage restraint measurement systems (GRMS), which help find weaknesses in fastening systems and track gage strength

- Improved rail profile grinding to promote better steering in curves

- Use of top-of-rail (TOR) friction modifiers, which reduce lateral loads and L/V ratios

- Automated tie inspection systems

The combination of all these technologies and practices has helped dramatically drive down the number of wide-gage derailments, Wolf said.

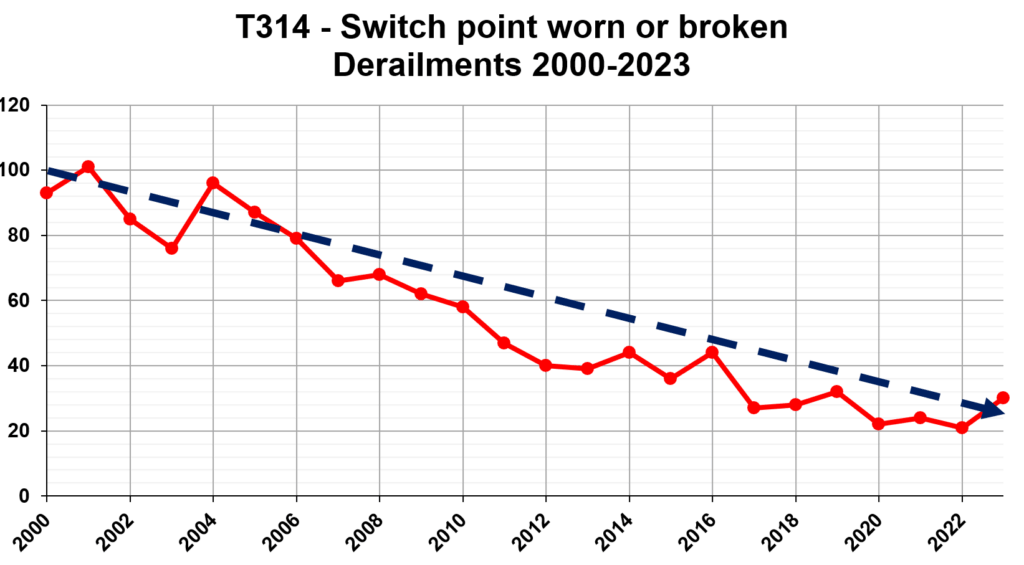

T314 – Switch Point Worn or Broken

The downward trend in these derailments (see figure 5) is also the result of a number of (relatively) recently developed and adopted technologies. As in wide-gage-derailment reduction, automated inspection vehicles have played a crucial role in identifying potentially problematic switches. Some railways have also adopted a voluntary alternate standard to guide their inspectors in determining when a switch point requires maintenance or remediation, Wolf said. Norfolk Southern, with a grant from the FRA in 2015, for example, developed a switch-point gage that simulates contact from a heavily worn wheel flange. “This is an excellent diagnostic tool. Any time you can put a gauge on something, it’s much better than putting your eyeball on it.”

RNT and T109 – Track Alignment Irregularity (Track Buckles and Sun kinks)

“Sun kinks are not caused by the sun; they’re caused by improper maintenance practices,” Wolf said, improper practices that include: failure to control rail neutral temperature (RNT), failure to maintain ballast section, failure to maintain good anchor patterns according to the CWR (continuous welded rail) plan. But progress has been made in reducing these cause codes, as well. “Staking of curves to ensure they’re not moving during the winter months is a great maintenance practice,” he said. Various stress monitoring technologies have helped, as has vertical rail stress equipment (VERSE) testing. VERSE testing requires unclipping the rail, a labor-intensive process, but it identifies true rail neutral temperature, Wolf said, which is an invaluable metric. “Every year, your neutral temperature is going to decline, especially in curve territory, so it’s a constant battle to keep the RNT where it should be.” The continued development (and implementation) of rail stress monitoring technologies can help railroads stay on top of the issue, he said.

Soft or Settled Roadbed

“T001 roadbed soft/settled; this is one I don’t quite understand,” Wolf said. He surmised that a number of railroads may use this cause code rather than citing a specific track geometry defect. A soft roadbed often leads to defects like twist, warp, surface profile, and alignment. But a roadbed defect must cause a geometry defect in order for a train to derail, he said. He suggested that the T001 cause code should be eliminated or revised so that railroads are required to cite a specific geometry defect or defects as their derailment cause.

Wolf also noted that cause code T109 (buckled track) similarly lacks specificity and is in fact incidental to some other root cause of the derailment itself. Cause code T222 (worn rail) lacks both specificity and any sort of objective metric; “The FRA has no standard for rail wear, so how can T222 be applied appropriately?”

Broken Rail Cause Codes

The cause codes that make up the broken rail group that have all declined since the year 2000 include:

- T202 – broken base of rail

- T221 – vertical split head

- T220 – transverse/compound fissures

- T210 – head and web separation (outside joint bar limit)

In many cases these declines have been dramatic, though all have been steady in their progress, Wolf said. Among the broken rail cause codes, however, T207 (detail fracture – shelling/head check) is an outlier. Since 2000, the trend has been a flat line. “Detail fractures are a self-induced problem,” he said; they’re largely due to:

- Failure to control rolling contact fatigue (RCF)

- Failure to grind

- Failure to grind properly (for example, improper rail profile or poor grind quality index)

- Failure to ensure crack propagation (RCF) is arrested

- Failure to properly elevate curves (resulting in excessive gage face contact forces and shelling)

- Failure to properly manage friction (lubrication and TOR friction modifiers)

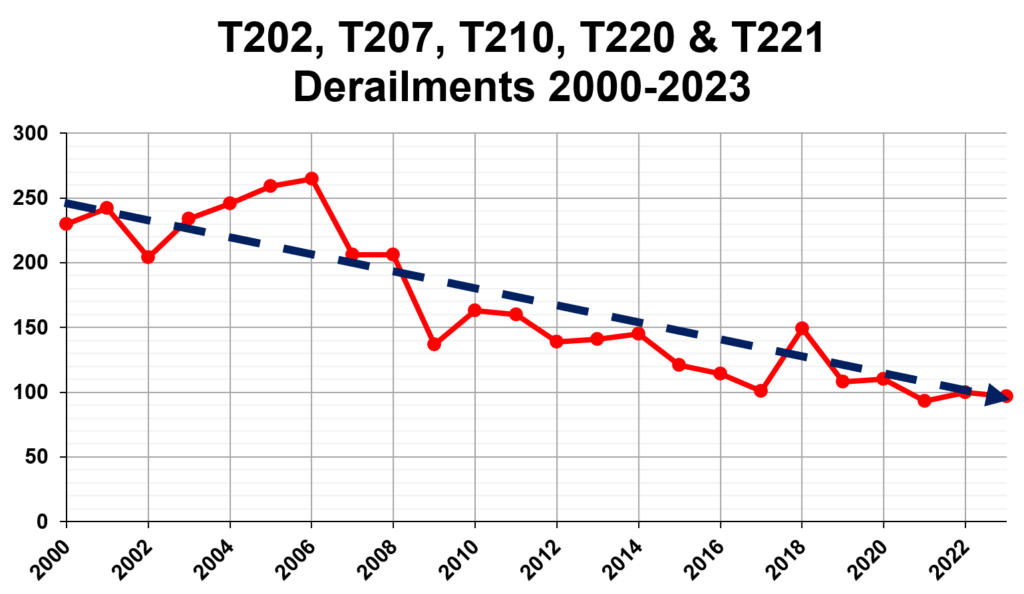

Nonetheless, when all the broken rail cause codes are taken in aggregate (including T207) the downward trend in derailments is significant (see figure 7). Wolf attributes the decline to concerted efforts and a number of complimentary factors over the past ≈25 years:

- Better testing frequency and regulatory testing requirements

- Better data analysis and visualization

- Better ultrasonic transducer technology

- Continuous testing versus stop-and-verify

- Better and more thorough training and certification of operators and inspectors

- Better rail grinding techniques with a stronger focus on RCF removal

- Expanded use of wheel impact load detectors (WILDs) to reduce high impacts

- Better compliance with rail wear limits

- Better welding practices in both plant and field

- Better rail steels

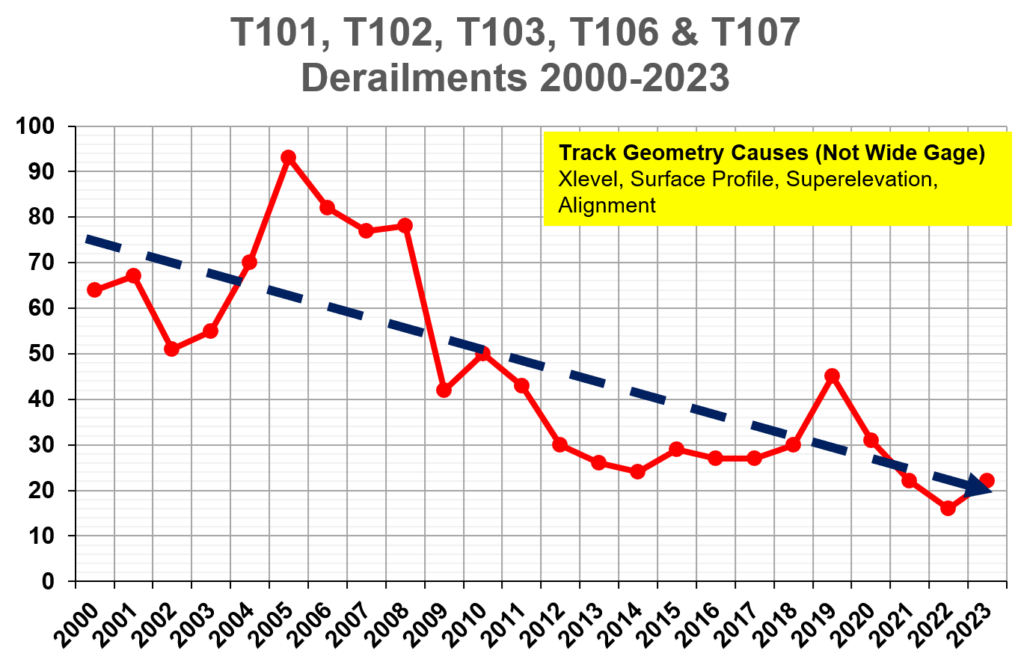

Track Geometry Derailments

Non wide-gage track geometry derailments—cause codes T101 (cross level at joints), T102 (cross level not at joints), T103 (surface profile), T106 (superelevation), T107 (superelevation runoff)—have also seen a steady reduction since 2000. Wolf attributes this reduction to several technologies, many of them part of autonomous track inspection programs (ATIP), and others used in hi-rail applications. “At an FRA symposium several years ago, every railroad that reported their results of ATIP showed very positive reductions in the number of track defects,” he said.

It’s also important to note that geometry defects can and often do contribute to or precipitate other derailment causes, like broken rails and joint bars, track buckles, wide gage, and switch derailments, Wolf said. “Track geometry defects fundamentally alter wheel/rail conditions and internal rail stress; the cause of a switch derailment might, in reality, be a mud spot 50 feet away causing a twist or warp defect.”

Continuing the downward trend of geometry-caused derailments means further embracing proven and emerging technologies and practices, he said. “The continued deployment of ATIP is necessary; the FRA needs to re-institute the waiver process to incentive ATIP investment and innovation.” He also praised the use of big-data-driven algorithms and AI to categorize, prioritize, and even predict defect development and remediation.

Room for Improvement

The list of successes in derailment reduction is long, and the data reflects it. But, Wolf said, there are pain-points that remain. “Broken and sheared spikes continue to be a problem in certain areas.” These are particularly prevalent in areas with high traction and dynamic braking effort, in sharp curves, and particularly in track with wooden ties.

Curve elevation is another area ripe for optimization. The increased prevalence of longer trains means that curve speeds now may be slower than they were five years ago, Wolf said; “you need to keep an eye on what your actual train speeds are—not what the timetable says—and ensure that your curves are elevated properly.”

“I’m a huge proponent of friction management. If you can dial in your [gage-face] lubrication and TOR [friction modifiers], you’re going to see a 30%-40% reduction in lateral curving forces,” he said; this is on top of proven benefits to reductions in rail wear, RCF development, and tie plate cutting. Unfortunately, siloes still exist in railroad budgets, and this can cause squabbling when it comes to who pays and who benefits from friction management programs. “It’s outrageous. We have to find a way to incentivize all parties in the rail system.”

Attributing derailments to the proper root cause requires ongoing effort. Too many so-called wide-gage derailments are in fact mechanical or operational in nature. It’s important to pay closer attention to factors like wedge rise, side bearings, truck warp, hollow-worn wheels, as well as train handling and in-train forces (buff and draft); “don’t just look at the ties and call it a day,” Wolf said.

Despite the various cause codes and the many track and mechanical issues that can contribute to a derailment, it’s important not to ignore the human component. Failure to inspect, failure to find a defect, failure to repair it or properly resolve an issue, even failure to provide adequate capital and budget—these, too, all contribute to derailments, Wolf said. This is why he prescribes a multi-prong approach to continuing the trend of decreasing derailments. It’s an undertaking that requires the synthesis of human, technological, operational, managerial, and regulatory action.

Jeff Tuzik is Managing Editor of Interface Journal.

This article is based on a presentation made at the 2024 Wheel/Rail Interaction Heavy Haul conference.

All images are courtesy of Gary Wolf unless otherwise noted.