Norfolk Southern Embarks On a New Approach to Rail Defect Repair

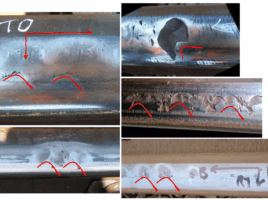

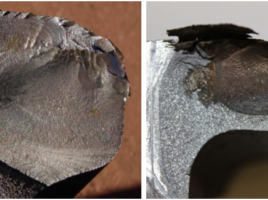

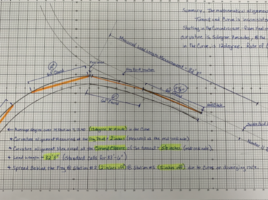

by Jeff Tuzik Some information in this article has been updated since the original publication date. Internal rail flaws and defects are an unfortunate but unavoidable part of railroading. All railroads have them. All railroads have to repair them. Defect remediation, which involves cutting out the affected rail and replacing …