30 Years of Evolution in the Field of Wheel/Rail Interaction

by Jeff Tuzik

What do 30 years of advances in wheel/rail interaction look like? Thirty years ago, the field of wheel/rail and vehicle/track interaction was largely unknown outside a coterie of specialists and researchers. Railroads operated within confined departmental siloes with vehicles on one side of the ledger, track on the other. But some experts and forward-thinking practitioners were beginning to share information, theories, data, and to conceive of and treat vehicles and track as parts of an interconnected system—an understanding that fundamentally changed some of the ways railroads design, operate, and maintain their systems.

Mike Roney, retired General Manager of Track and Structures and Chief Engineer at Canadian Pacific and Principal of Iron Mustache Consulting, was on the front lines in the early days of the wheel/rail interaction “boom.” His work at Canadian Pacific (CP) to implement a cyclical preventive rail grinding program, and to develop large-scale lubrication and friction management programs, is often cited today as being highly effective and ahead of its time. (See: Mike Roney Receives the 2025 Worth Award – Interface Journal and Management and Maintenance: Capitalizing on Friction Modifiers – Interface Journal for more information on these programs.)

“When I look back on 30 years of wheel/rail interaction and conferences like these, I’ve seen a steady progression of knowledge from questions and theories to practical applications and real-world data.” -Mike Roney

Speaking to colleagues at the 2025 Wheel/Rail Interaction Heavy Haul Conference, Roney discussed some of the ways in which the principles of wheel/rail interaction have moved from theory to practice, and how they have evolved, over time.

The Unknown

With the advantage of hindsight, Roney said, there are many examples of wheel/rail interaction issues that the industry was largely unaware of—and thus had no relevant data on, or maintenance strategy to address—30-plus years ago. These include things like the deleterious effect of hollow worn wheels on rail profile, steering and curve performance, and rail rollover potential. Another blind spot was the effect of high friction levels on wheel and rail wear, wheel-climb derailment potential, and wheel/rail interaction in general; friction management was not yet a fleshed-out concept. There were many such overlooked issues, Roney said:

- The cost and prevalence of high-impact wheels.

- The cost and prevalence of “bad actor” cars, which are responsible for a disproportionate amount of track damage.

- The effects of low truck stiffness in three-piece trucks, particularly low truck-warp resistance.

- The derailment risk posed by torsionally-rigid empty tank cars in spirals and S-curves.

- The effects of deviation from stress-free/rail neutral temperature. “We could have saved ourselves a lot of trouble if we had keyed into the precise relationship between stress-free temperature and track buckles and cold weather rail breaks earlier on,” he said.

- Rail rollover risk associated with flattened rail.

- The impact of clustered, rather than individual, track geometry defects.

- Longitudinal dynamics (i.e. buff and draft forces) in long trains and their effect on vehicle/track interaction.

This isn’t an exhaustive list, but rather a snapshot of some of the most important issues that eluded the industry’s attention in the past, but have since been heavily studied and scrutinized, and to varying degrees remediated.

The Known

No longer obscure, the use of gage-face lubrication and top-of-rail (TOR) friction modifiers is now standard practice on most railroads. Mike Roney is, in fact, often praised by colleagues for his early recognition of the benefits of lubrication and TOR FM, and for implementing highly effective friction management programs on Canadian Pacific’s Western Corridor.

“Other railroads were dabbling in friction management at the time,” Gary Wolf, President of Wolf Railway Consulting told Interface Journal. “But Mike was a true pioneer. And he set a very high bar with the work he did at CP.”

Railroads have also become much more conscious of rail stress and neutral temperature. In addition to ensuring that new rail is laid at the appropriate neutral temperature, many railroads monitor RNT and take preventive measures in advance of seasonal temperature swings, such as unfastening and de-stressing the rail, or less commonly, painting the web of the rail white as is done in other parts of the world (Mitigating Track Buckling on São Paulo’s Metropolitan Train Network – Interface Journal) to better reflect sunlight and reduce heat absorption. Railroads are also more proactive in issuing hot weather speed restrictions when temperatures are particularly high, for example. This is not a solved issue; track buckles and pull-aparts still occur. And there is still no generally agreed upon “perfect” method for measuring RNT in-situ (without having to unfasten and/or cut the track) and in real time. But there has been undeniable progress.

The cost of high-impact wheels is another area in which railroads have made tremendous progress. Wheel impact load detectors (WILDs) are now a 50-year-old technology. They are now also ubiquitous. The physical and economic consequences of high-impact wheels are well understood and well documented (see Data to Decisions: Tools and Technology to Manage Wheel/Rail Interaction – Interface Journal for more information). Railroads have also developed novel ways to leverage WILD data beyond its original purpose, such as load-imbalance detection and wheel-defect trending.

“As an industry, we’ve learned a lot about wheel/rail interaction in the past few decades and we’ve built up a shared knowledge base,” Roney said. He considers the following to be among the most important “lessons learned” during this period:

- Wheel profiles can be designed such that they improve steering while also mitigating hunting—it’s not an either/or situation.

- Tighter specifications on three-piece trucks (i.e. the M-976 spec) can improve curve negotiation; frame-braced or steerable trucks are not necessary to realize these benefits.

- WILDs can effectively identify “bad actor” cars.

- Low-speed wheel-climb derailments are preventable. “Higher flange angles in the wheel profile go a long way toward mitigating [such derailments].”

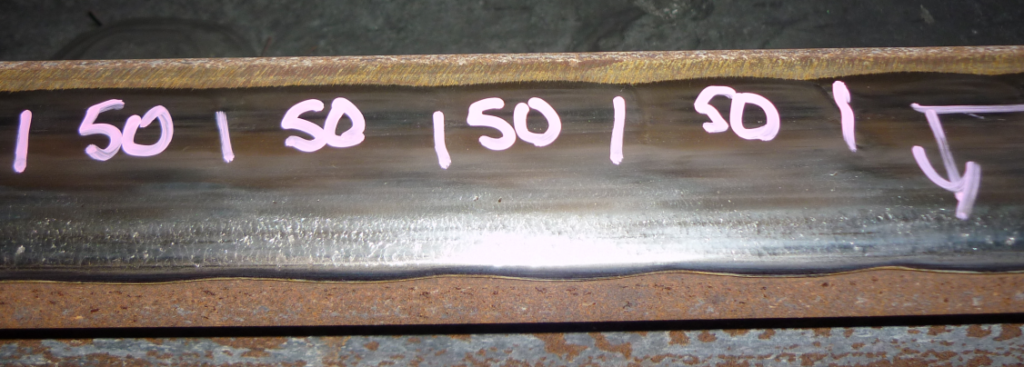

- Preventive rail grinding can control the development of rolling contact fatigue. “RCF, it turns out, is entirely preventable, with the right grinding cycle.”

- Nonstop rail-flaw detection allows for tighter test intervals and greatly reduces the risk of rail failure.

- Managing RNT is possible, but requires diligent monitoring and intentional (and time-consuming) field practices.

- Concrete tie rail-seat abrasion can be mitigated through various components and technologies designed to prevent moisture and particulates from getting between the rail pad and the tie.

- Long trains can be run more productively and less destructively using distributed power.

- Computer assistance can help train drivers limit the severity of in-train (buff and draft) forces.

From a contemporary perspective, some of these points may seem self-evident. But it’s important to note that any practice or technology introduced to the railroad ecosystem requires extensive research, testing, validation, and economic justification, Roney said. In addition, some benefits are realized over long time periods and high MGT, meaning studies and validation can last years or decades. This knowledge is hard-won—the result of collaboration between—and research by—railroads, organizations like the NRC and the former TTCI and work done at the TTC, along with universities, and suppliers.

The railroad industry is not known to be particularly fast-changing or disruptive. Yet, the last ≈30 years have seen great advances in many fields, particularly that of wheel/rail interaction.

“The pace of change today may be a bit slower than it was in the past, because individual railroads acted more autonomously then. But, because railroads work more collaboratively now, when changes do occur, they affect the entire industry at once—the rollout and adoption of autonomous track inspection programs is a good example of this.” –Mike Roney

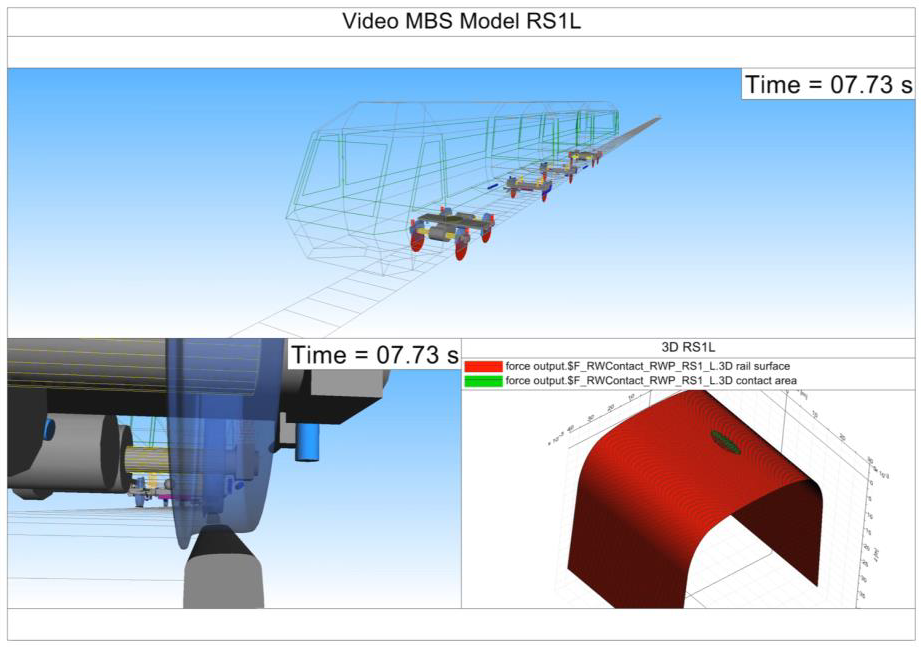

Modern technologies like automation, machine learning, and sophisticated modelling and simulation software have no doubt contributed to many of the sweeping, industry-wide changes Roney discussed. Technological advances will help shape the next 30 years of wheel/rail interaction. But optimizing a railroad will always, ultimately, come down to skilled, progressive experts turning theory into practice.

Jeff Tuzik is Managing Editor of Interface Journal

This article is based on a presentation made at the 2025 Wheel/Rail Interaction Heavy Haul Conference.

Lede Image: ENSCO