Mitigating Track Buckling on São Paulo’s Metropolitan Train Network

by Jeff Tuzik

On passenger rail systems, disruption is never good. With tight headways and packed cars, a small disruption of service doesn’t stay small for long. Major disruptions, such as those that require taking a track out of service for repair, are worse yet. On São Paulo’s Metropolitan Train network, ViaMobilidade recently implemented a number of maintenance and mitigation measures aimed at reducing disruptions caused by track failure—track buckles in particular—and doing so in an efficient, cost-effective manner.

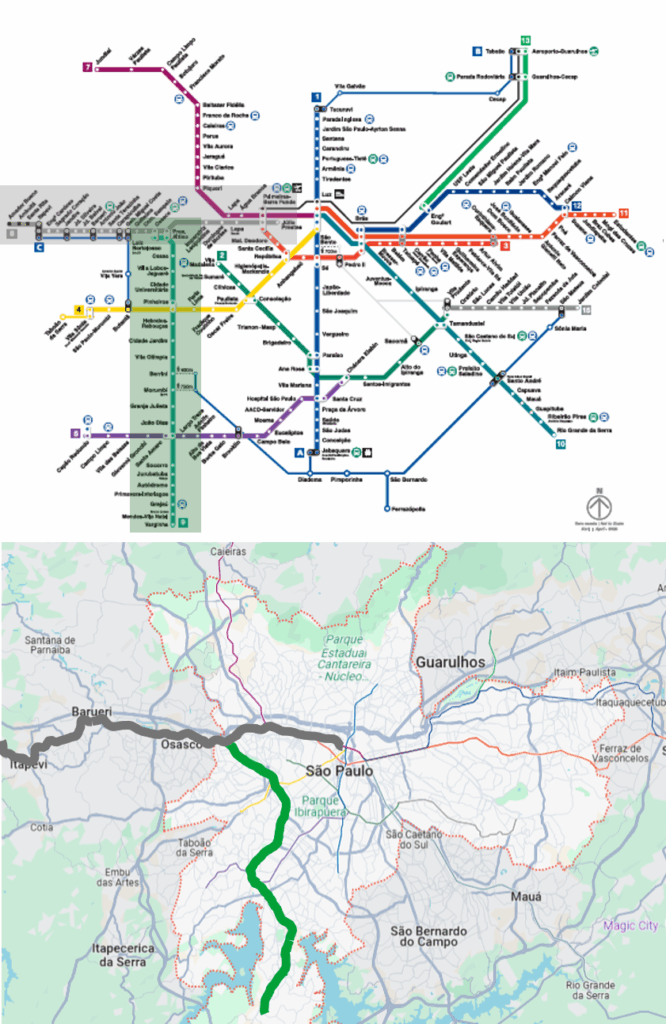

ViaMobilidade (VM), part of Motiva, became the operator of São Paulo Metropolitan Train Lines 8 and 9 in 2021 under a 30-year contract. Lines 8 and 9 are commuter lines which, combined, make up 87 track miles and have a daily ridership of ≈800,000 passengers (Figure 1 highlights the location of Lines 8 and 9).

The track infrastructure on Lines 8 and 9 is varied. Rails are primarily 115RE (53%) and 100RE (43%) with a small amount of 60E1 (4%). The track is ballasted with wood ties on 62 percent of the system and concrete ties on the remaining 38 percent. Other track components vary widely. “We use a large variety of elastic fastener types. These various non-standardized components were inherited from the previous operator,” said Paulo Lobato, Technical Consultant for Permanent Way Maintenance at Motiva, addressing delegates at the 2025 Wheel/Rail Interaction Rail Transit Conference.

VM also inherited some sub-optimal track conditions on both lines. Beginning in 2023, VM began to track failures and their causes on Lines 8 and 9. The top three track failure modes in 2023 were broken rails, track buckling, and surface and crosslevel defects. Track buckles accounted for 23% of all failures (a total of 31).

“São Paulo is very dense, and ridership is high. Any track disruption can become chaotic quickly,” Lobato said. Figure 2 is a photo of a station during one such disruption. Since VM became the operator of Lines 8 and 9, they have invested heavily in mitigating track failures, with a special emphasis on track buckling. Large scale, disruptive remediation efforts are impossible because neither ViaMobilidade nor the system can tolerate additional closures or disruption, Lobato said. As a result, VM has focused on less-intrusive mitigation techniques aimed at driving down the frequency of specific failure modes.

Track Buckling

Track buckling is the direct result of rail steel expanding due to heat. When rails are heated, they expand, or attempt to expand, longitudinally. Elastically-fastened rail, such as the rail on Lines 8 and 9, is constrained from longitudinal motion and expansion by the ballast, ties, and fasteners, and by the rail abutting the heated section. “Because the rail can’t elongate longitudinally and is under great compressive force, it “finds” weak spots with lower lateral resistance where the track can shift sideways to accommodate thermal expansion,” Lobato said. A track buckle occurring beneath a train can be forceful enough to cause a derailment; Figure 3 shows an example of such a derailment that occurred in Rio de Janeiro in early 2025. According to local reporting, the rail temperature reached 149 degrees Fahrenheit when the track buckled. “It takes careful engineering to prevent track buckles like these in Brazil’s hot climate,” he said. In the São Paulo region, rail temperatures typically range from 4 to 62 degrees Celsius (≈39 to 144 degrees Fahrenheit) depending on the season.

Since 2022, VM has implemented a track-buckle mitigation program that includes multiple maintenance practices and solutions. But the first step was updated training and education. It’s critical that track maintenance personnel understand why they’re doing what they’re doing on track, what they can do to help prevent track buckles, and what to do if, or when, a track buckle occurs, Lobato said.

“Because we only recently began operating Lines 8 and 9 there is some historical data we don’t have, such as the temperature at which the rail was laid,” Lobato said. Lobato said he suspects the rail was laid at night (at low temperature) and likely was not pre-stressed. These conditions predispose the rail to track buckling.

So, in order to monitor rail temperature in-situ, and to be on alert when temperatures are conducive to track buckling, ViaMobilidade installed rail thermometers at several locations on Lines 8 and 9. These are simple sensors installed, via a small hole, bored into the web of the rail (see Figure 4). There are currently six sensors installed across both lines, distributed to monitor a range of temperatures characteristic of the lines at large, he said.

The sensors collect and transmit data in real time, delivering it to a web-based platform where maintenance and operations personnel can access it. The system also sends out automatic alerts when specific temperature thresholds, both high and low, are met so that heat inspections can be performed and slow orders issued. “Even when the alerts don’t prevent a rail rupture or track buckle, they help us prepare in advance and react quickly, minimizing service disruption,” he said.

ViaMobilidade has begun to de-stress rail, as well. But like most transit systems, access to Lines 8 and 9 is constrained by very tight maintenance windows. “We only have a three-hour work window for maintenance and, as of now, we haven’t found an efficient or effective way to implement this procedure,” Lobato said.

Both to mitigate track buckling and as part of general system revitalization, VM is in the process of replacing wood ties with concrete and reinforcing ballast. Both of these efforts increase the lateral resistance of the track, which in turn reduces the likelihood of track buckling, Lobato said.

In 2024, VM began to paint some of their rails white. “As we know from high school physics, white reflects sunlight very well,” Lobato said. “We expected this practice to reduce heat absorption and rail stress, which should reduce the frequency and magnitude of track buckles.” The paint is applied to the web and base of the rail (see Figure 5), leaving the rail head clean and uncompromised from a traction and braking perspective. Currently, paint has only been applied to the rail in areas of track that are known to have a high occurrence of track buckles.

Video 1 shows the rail-painting machine in operation. “We developed this equipment in-house with a very limited budget,” he said, “but as you can see, it performs very well.” Yard tests of the painting program indicate that white paint can reduce rail temperature by up to 8-degrees Celsius (14.4-degrees F), depending on weather conditions and time of day. VM is currently using a simple water-based paint, but is also considering more specialized paints.

“These are simple practices that we’ve implemented, but they’ve been successful,” Lobato said. Compared to data collected in 2023, shortly after VM took over operation of Lines 8 and 9, track buckles have now fallen by 61% (from 31 to 12 to incidents) and are now the fourth most common mode of failure, rather than the second.

Solving a problem like pervasive track buckling on a limited budget and with limited maintenance windows isn’t easy, Lobato said, but it’s pretty straight-forward. “You have to go back to the basics—make sure you’re addressing the root of the problem and make sure your solutions are well-implemented.” It’s also important that the maintenance practices that are put into place are sustainable—in the sense that practices can be sustained even when conditions or personnel change. This is where training is particularly important. It’s easier to sustain a maintenance practice that is understood and valued by an organization, than one that seems esoteric or driven by individual preferences.

ViaMobilidade’s approach to mitigating track buckling has, so far, not been to evaluate the efficacy of individual mitigation efforts or to compare one strategy to another, but rather to reduce the frequency of track buckles via the most cost-effective and least-invasive means possible. By this metric, the program is a success. But there’s room for improvement, too. These are early days for ViaMobilidade’s operation of Lines 8 and 9, but as they come to better understand their track and its characteristics, they plan to expand on the strategies they’ve implemented and continue to reduce track failures and service disruptions caused by track buckling.

Jeff Tuzik is Managing Editor of Interface Journal

This article is based on a presentation made at the 2025 Wheel/Rail Interaction Rail Transit Conference.

All images are courtesy of Paulo Lobato and Motiva/ViaMobilidade except where otherwise noted.