Studs: Squat-Type Defects that are Misunderstood and Mismanaged

by Jeff Tuzik

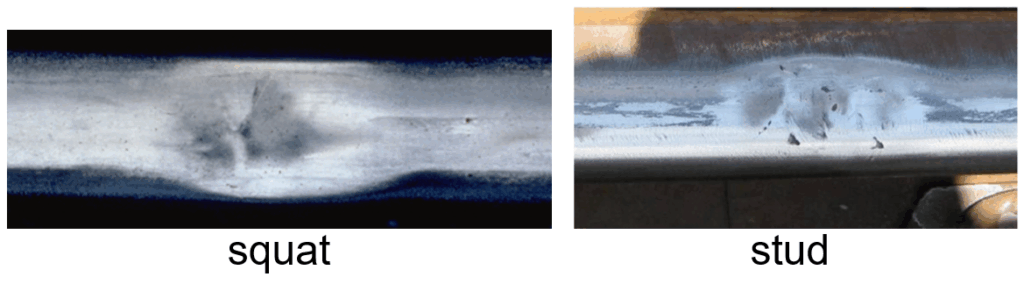

Squats and studs (squat-type defects) are a topic of discussion and debate in the world of wheel/rail interaction. Their similarity in appearance leads many experienced track people to misidentify them, and the urgency with which they need to be addressed.

As previously reported in Squats & Studs: Emergent Damage Mechanisms on Rail Transit Systems, squats and studs have a complicated and somewhat confusing history.

“Frankly, studs remain a quite poorly understood defect to this day,” Stuart Grassie, Principal of Rail Measurement Ltd / Stuart Grassie Engineering Ltd, and primary investigator of the stud phenomenon, told attendees of the 2024 Wheel/Rail Interaction Transit conference.

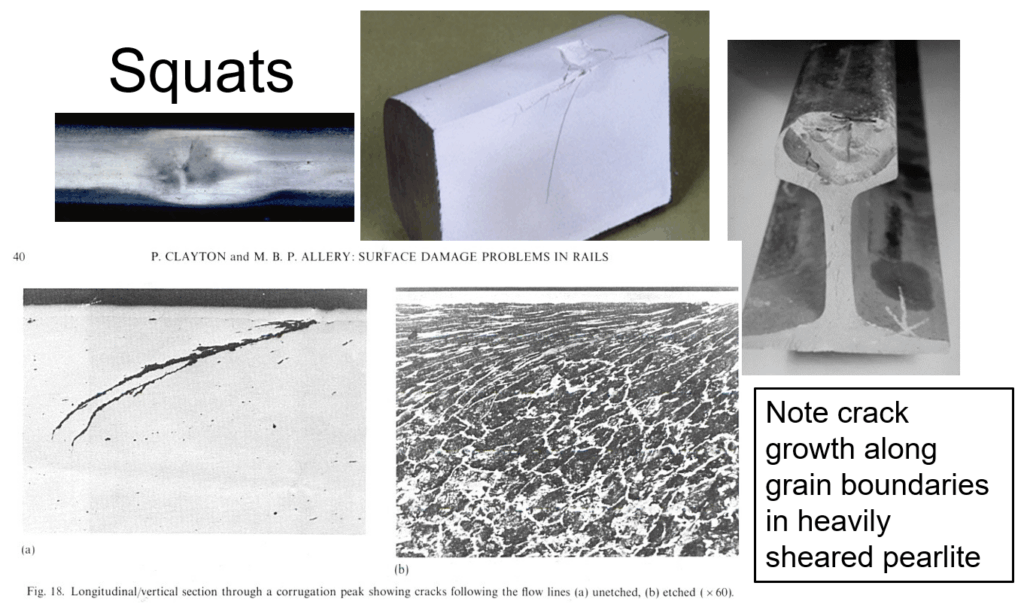

Squats

Squats were first identified on relatively high-speed rail lines like British Rail’s West Coast Main Line in the 1970s. Much work was undertaken by British Rail Research, which gave rise to published papers such as that shown in Figure 1. Squats tend to develop cracks that grow into the rail along grain boundaries in pearlite that is heavily sheared in the direction of (wheel) traction, Grassie said. “These cracks grow this way through the first few millimeters of the rail until they reach a depth where they grow under bending stress in the rail.” If left untreated, such a crack is likely to develop a transverse defect, i.e., a rail break.

Another characteristic of squats is that they develop quite slowly. “Squat crack growth is typical of general RCF development,” Grassie said. It generally takes ≈40 MGT for “seed cracks” to develop in the sheared pearlitic structure of the rail surface, and ≈100 MGT for the crack to reach the edge of the heavily sheared layer—the so-called elastic/plastic interface of the top few millimeters of the rail. “This slow development means there is ample opportunity to treat the defect before it progresses.”

A combination of factors, including harder rail steels and more sophisticated rail maintenance efforts like corrective and preventive rail grinding, had, by the 1990s, curtailed the proliferation and imminent danger of squats, Grassie said. “Squat-caused broken rails simply don’t exist anymore.”

Studs

Just as the concern over the danger of squats subsided, a new defect began to be noticed. These were first documented towards the end of the 1990s on heavy haul systems, and subsequently also on transit systems. Superficially, the defects looked very similar to squats (see figure 2). But Squats had been documented only on relatively high-speed passenger railways. This new defect was appearing on various types of railways worldwide. Because of their superficially similar appearance, they initially were thought to be squats; The prospect that squats we reappearing was alarming because of the numbers involved and their appearance on all types of railway system.

“Any rail defect requires attention. Defects that lead to rail breaks require immediate attention and remediation. The proliferation of these new squat-type defects found on all types of railroad systems—heavy-haul, metro systems, and high-speed passenger lines sent a wave of panic through segments of the industry.

Further investigation determined that what appeared to be squats were in fact a new phenomenon—a class of defects that Grassie termed “studs.”

Unfortunately, Grassie said, by the time that studs appeared, most of the experts who had performed critical, early research on squats were no longer active. “We lost a lot of institutional knowledge.” As a result, a widespread assumption has persisted in the industry that treatments that were relevant to squats, were also relevant to studs.

Gaining Understanding

While there are superficial similarities between studs and squats, Grassie said, there are significant differences. Significant progress has been made in cataloging these differences. They include:

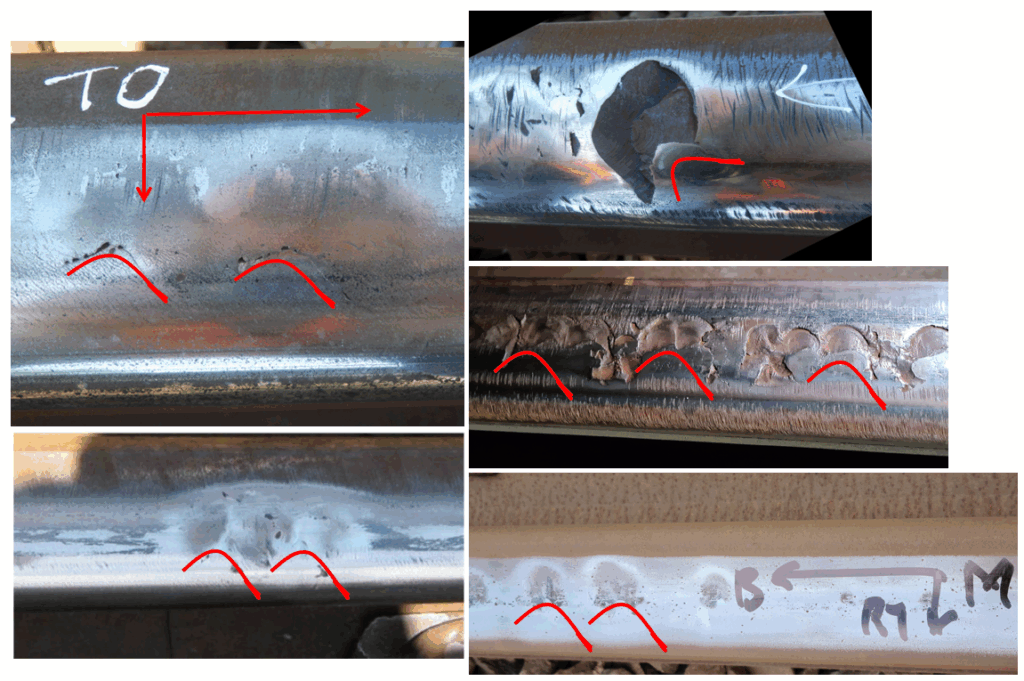

- Unlike squats, studs often appear in periodic patterns or clusters.

- Unlike squats, studs are frequently associated with spalling and shelling-out of the rail surface.

- While squats are typically associated with high-speed passenger lines, studs are found on all types of railroad systems—particularly on heavy-haul lines and metro systems).

- On the rail surface, cracks that develop into studs develop from a crack that appears like an inverted U or V shape (relative to the gage corner of the rail (figure 3). These grow across the rail, initially at an angle of about 20 degrees to the rail surface. After they reach a depth of about 3mm, they tend to grow across the rail. Eventually, they may rise to the rail surface and spall out. Most importantly, they do not grow down into the rail and develop under bending stresses.

- Most significantly, perhaps, “studs develop very quickly, typically in 5 to 10 MGT, and they’re often associated with spalling,” Grassie said. “This is very unlike squat growth patterns.”

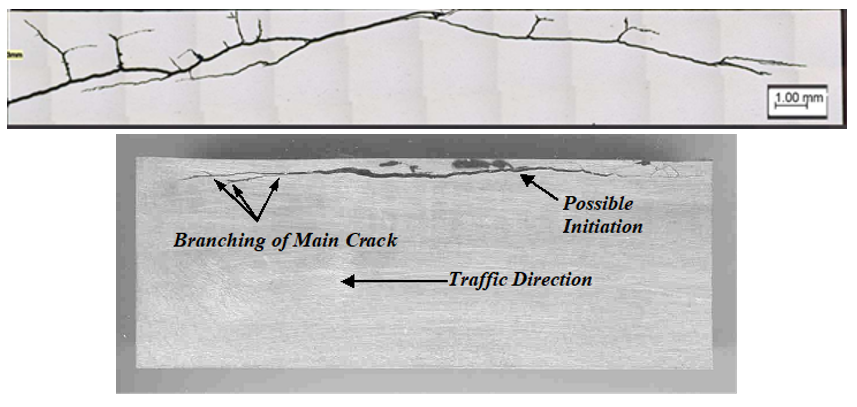

Cross sections of stud cracks examined by agencies like Transportation for New South Wales (TNSW), the National Research Council of Canada (NRC), and London Underground also showed that the cracks tend to “wander” (see figure 4) rather than follow the grain structure of sheared pearlite, as is characteristic of classical squats, Grassie said; “in many cases, studs develop in the complete absence of sheared pearlite.”

There is a great deal of evidence that studs are more common in harder rail steels. This is contrary to the universally accepted behavior of conventional rolling contact fatigue (such as head checking or indeed, squats), which develop more slowly in harder rail steels. Figure 5 shows such an example. The top rail is 1995 standard carbon rail with ≈20 years of traffic and no evidence of studs; the bottom rail is 2002 head-hardened rail in the same curve with only ≈10 years of traffic. Yet the head-hardened rail is in the process of being replaced due to the number and severity of studs.

There is some evidence that AC traction has a significant effect on the formation of studs. “[This research] indicates that studs tend to appear at the same location on opposite rails, often at a spacing matching that of axles on power cars,” Grassie said.

On London Underground, studs were commonly found on lines equipped with AC traction (the Piccadilly, Northern, and Central lines) but absent on lines operating under conventional DC traction. Similarly, Grassie noted that studs are not present on Vancouver SkyTrain, a system that uses a linear induction system to move trains rather than tractive effort.

“We’ve also seen that deliverable adhesion has increased with successive generations of AC traction in both transit vehicles and heavy-haul locomotives, just as studs have increased on these systems. It may be that we’re seeing the effects of controlled wheel slip.”

Building a Better Understanding

All of that said, the industry does not yet have a firm handle on the differences between squats and studs, due in part, no doubt, to their similar appearance. But it’s important to distinguish between them and understand the differences between them. In simple terms, the greatest difference is that squats break rails and studs don’t, Grassie said. “If we continue to apply the understanding we’ve built up about squats to studs, we’re wasting a hell of a lot of time and money,” he said. “We should not be treating a defect that is relatively benign (studs) like something that is extremely dangerous (squats).”

There is a predicament in which classical squats are well understood but extremely rare, and studs are extremely common but poorly understood. Grassie’s prescription is more, much more, research into studs—primarily how (and how quickly) they develop, and their relationship to AC traction and rail hardness. “This is an issue that should be tackled with the joint cooperation of both rail and vehicle suppliers,” he said. “Both stand to gain from the research.”

Jeff Tuzik is Managing Editor of Interface Journal

This article is based on a presentation made at the 2024 Wheel/Rail Interaction Transit conference and includes updates and information current as of July 2025.

All images are courtesy of Stuart Grassie unless otherwise noted.