Taking Stock of 30 Years of Wheel/Rail Interaction

by Jeff Tuzik

As Wheel Rail Seminars prepares to host it’s 30th annual Wheel/Rail Interaction Conference in Kansas City, it’s worthwhile to look back on how the “narrow” field of wheel/rail interaction has broadened and matured over the decades.

The field of wheel/rail interaction is highly targeted; focusing on the systemic effects of everything that happens where the wheel meets the rail. The wheel/rail contact patch—about the size of a dime—may appear to be a miniscule area of focus to the uninitiated, but it’s the point at which everything—vehicles, track, operations, and the laws of physics—all comes together. And as the theory and practice(s) in the field have evolved, the topic has come to include a growing suite of technologies, methodologies, and additional fields of study. The core elements that have been part of the WRI discussion for decades also continue to evolve.

Ten years ago, we looked at the state of the art in wheel/rail interaction through the lens of the topics covered, the discussions generated, and how the management of wheel-rail/vehicle/track interaction had evolved over the previous 20 years (Part 1 and Part 2). This article follows from there to provide a snapshot of some of the more recent advancements in technology and maintenance practices and the development of new issues to resolve.

Some of the advances of the past decade are part of a pattern of steady, incremental improvement, such as more sophisticated metrics-driven rail grinding programs, or the development and adoption of new friction modifiers, and harder wheel and rail steels. Some of the advances represent the synthesis of many theories and practices that have existed disparately in the industry, but never implemented together, such as in transit systems designed from the ground up to eliminate corrugation development.

And some advances are the result of advances in technology and were simply not possible a decade ago; this includes things like powerful and convenient multibody simulation tools, autonomous track and vehicle inspection technologies, and others.

These topics and others, which have been presented at Wheel Rail Seminars’ Wheel/Rail Interaction conferences in years past, represent the state of the art in the field, and set the stage for future advances.

Damage and Defects, New and Old

Corrugation isn’t a new topic, but it’s always a relevant one. Transit properties have used technologies like corrective and preventive rail grinding, friction modification, and wheel/rail profile optimization to mitigate corrugation formation for decades. But it has also become increasingly common for properties to work with specialists to dig deeper to find the true root cause(s) of their corrugation—a process that requires a thorough analysis of resonances in the system, including both vehicle and track components.

Every component in the system including wheels and rails, wheelsets, axles, rail fasteners and ties, has a resonance, said Eric Magel, Principal of EM-WRI Consulting Inc., and former Principal Engineer at the National Research Council of Canada. “And where there is resonance, there is potential for a feedback loop.” Such feedback loops are at the root of corrugation (see The Tools of Remediation: Case Studies on Mitigating Common Concerns at the Wheel/Rail Interface for more information).

Seattle’s Sound Transit, which is the local host for the WRI 2026 Rail Transit conference, uses these types of analyses to help guide their corrugation mitigation and wheel/rail optimization programs. They were able to determine, for example, that a rough grind signature in one section of track induced a resonance that led to multiple instances of rail clip failure in the University Link tunnel, said Shankar Rajaram, Executive Project Director – Revenue Vehicles, Operations Department at Sound Transit.

Squat-type defects (studs) have also been a frequent topic over the past decade. These defects, which largely began to appear on UK and EU transit systems in the 1990s, are now common throughout the industry. Early studies primarily focused on attempting to define the characteristics of studs versus the similar, but more severe defect: squats. (see: Squats and Studs: Emergent Damage Mechanisms on Rail Transit Systems).

Subsequent research efforts have indicated that the two defects are functionally distinct entities, despite their similar appearance. And studs, luckily, do not carry the same risk of rail break that squats do, Stuart Grassie (who pioneered much of the early research on studs) told those attending last year’s WRI conference.

However, studs are still not fully understood, despite their common occurrence. They are thought to be causally associated with AC traction and wheel-slip; they tend to co-occur with the transient formation of white etching layer(s) (WELs), which are thin martensitic patches formed on the rail due to extreme heat (wheel slip events); and they appear to be related to corrugation formation, although whether this is causative or correlated isn’t fully understood, Grassie said.

The emergence of “new” defect types like studs, and the commonality of other rail (and wheel) surface and subsurface defects also highlights the way inspection technologies have evolved over the past decade.

Inspection Technologies

Rolling contact fatigue (RCF) is a defect found on both heavy haul and transit systems worldwide. Cyclical preventive grinding programs are the generally adhered-to industry standard for mitigating RCF growth, and these programs tend to work well.

But aside from the damage done to the rail, RCF is troublesome in that it can obscure defects from ultrasonic internal flaw detection. Ultrasonic inspection, on the other hand, lacks the ability to detect only near-surface internal flaws, meaning there is an “unknown” gap in the rail between visual and ultrasonic inspection, said Eric Magel.

There are now multiple inspection technologies in use in North America (and abroad) that focus on near-surface rail flaw/crack detection. These systems are based variably on eddy current, magnetic flux leakage, or other magnetic field imaging technologies and typically measure from the surface to ≈5 mm to 7mm into the rail. (see Measuring With Eddy Current: Gage Corner Cracking and the Magic Wear Rate)

In the past 10 years, RCF measurement (in North America) has gone from niche to fairly common, particularly as part of rail grinding programs, to ensure the bulk of the targeted RCF damage has been removed. Originally, these devices were manually operated push-along units (any many still are), limiting data collection to walking-speed over short distances. Recently, however, some of these technologies have been adapted for hi-rail and rail inspection vehicles, enabling broader application and collection, Magel said.

But RCF detection is not a solved problem. Refinements to near-surface inspection technologies have increased confidence in their results, but room for improvement remains; one limitation of these technologies is that they tend to be more accurate in measuring the density/severity of RCF damage in aggregate, rather than the characteristics of individual cracks within the RCF, Magel said.

Autonomous Inspection

Autonomous inspection technologies have existed in some form for many decades. But the accelerating shift toward more, and more sophisticated, automation has also radically changed the way railroads and transit systems collect and leverage track and vehicle data on their systems, said Allan Zarembski, Director of Railway Engineering and Safety at the University of Delaware in a 2015 presentation.

The ease of storing and transferring large quantities of data and the full or partial automation of data processing have helped to facilitate these changes.

“There’s decades of evidence showing that automated track geometry testing is more effective than manual inspections,” said Brad Kerchof, former Director of Research and Tests at Norfolk Southern, in a 2022 presentation. Indeed, by the early 2020s, North America’s largest railroads (Burlington Northern Santa Fe, Canadian National, Canadian Pacific (now CPKC), CSX, Norfolk Southern, and Union Pacific) were all investing heavily in, and running automated track geometry systems of some type. These systems did not replace existing geometry testing programs due to FRA regulations requiring manual track inspection (except in the case of waivers granted for certain test programs) but have existed alongside them and provided the railroads with troves of valuable data.

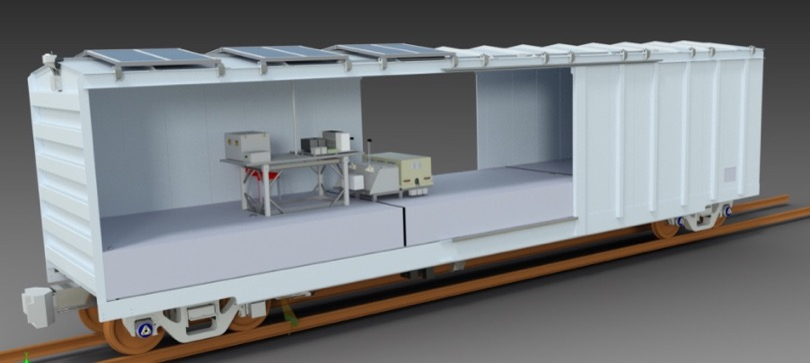

These systems, many of which operate in revenue service (such as via instrumented boxcar or locomotive), are not limited to measuring track geometry. Many include machine vision technologies for performing “visual” inspection of the rail surface, ties and fasteners, and laser profile measurement systems as well. Some include instrumented couplers to measure buff and draft forces; there is effectively no limit to what can be measured. But it all adds up to a tremendous amount of data. And what good is data if it isn’t being used?

“Data and decision management are the biggest things we’re going to face over the next couple decades,” said Matthew Dick, Director of Business Development at ENSCO, in a 2015 presentation. Processing all this data can easily become a bottleneck that prevents an organization from acting on the most relevant information in a timely manner.

This has held true in the years since; many railroads have run into issues with data that is siloed by various groups or simply stored in separate databases, thus preventing certain types of analysis that require the correlation of multiple data streams.

Modelling and Simulation

Inexorable advances in computing power have, among other things, made modelling and dynamic simulation tools more convenient, more powerful, and faster than ever before. These kinds of simulations have many powerful applications in the wheel/rail interaction space.

Wheel and rail profile design has always been a critical component of optimizing wheel/rail interaction. Wheel and rail profiles have historically been evaluated (for their stability, L/V performance, and derailment propensity) through quasi-static simulation. These simulations are valuable and still a key component of wheel/rail profile design.

Multibody dynamics simulations, which are more computationally intensive, enable engineers to more accurately “measure” (simulate) real-world wheel/rail contact conditions prior to implementation, said Alexandre Woelfle, a Project Engineer in the Wheel/Rail Interaction and Performance group at the National Research Council Canada (NRC), in a 2024 presentation. These simulations can also model dynamic forces acting on/imparted by the bogie and carbody, all of which affect both contact conditions and vehicle stability.

Grinding and Milling

The fundamentals of rail grinding haven’t changed much in the past decade, but railroads in the heavy haul and transit industries have continued to refine their grinding strategies and creatively leverage grinder capabilities to maximize the effects of their overall grinding programs.

CSX overhauled its grinding program roughly 10 years ago in order to refocus on non-testable areas (track sections in which the surface condition is too poor for ultrasonic testing) and by extension, gage corner cracking and transverse defects. CSX adjusted their grinding schedule based on historical wear and RCF data, and developed a metric for minimum depth of cut at the gage corner in the presence of RCF. Ten years after the implementation of this new strategy, CSX’s non-testable areas were down to less than 1% of the figure at program start, Dan Hampton, Director of Contract Services at CSX, said in a 2024 presentation.

Sound Transit has also found success in fine-tuning their grinding program. As a transit system in a densely populated city, excess noise and vibration are of primary concern. To cut down on the noise, they worked with their service providers to implement a grinding program that would first remove corrugation and correct the rail profile with standard low-grit or coarse grindstones, then switch to high-grit or fine stones to perform an acoustic or “polishing” grind.

The acoustic grinding step functioned to reduce surface roughness, and to ensure that the remaining grind signature didn’t coincide with any known system resonance or problematic noise frequencies, Sound Transit’s Shankar Rajaram said in a 2018 presentation.

The latter step involved experimenting with multiple types of grindstones and various grinding parameters (such as speed and applied power), but ultimately achieved the results Sound Transit was looking for.

After many years of discussion, rail milling arrived in North America. Although the practice is well established in Europe, East Asia, and Australia, rail milling has been slow to catch on in Canada and the US. But in 2017, the Toronto Transit Commission (TTC) published North America’s first milling service tender, and entered into a multi-year contract.

The TTC brought in a milling machine to target specific sites considered too sensitive for their standard grinding operations: this includes areas with a high fire-hazard, and in or near stations where (grinding) dust and subsequent cleanup are of paramount concern.

Milling has long been touted as a complimentary technology to rail grinding, best suited to just the sort of applications the TTC has identified. The results of this project are sure to be of interest to other NA transit properties.

It’s useful—essential—in fact, to stop and reflect on what we’ve learned about the dos and don’ts of wheel/rail interaction over a generation of railway engineering. It’s equally important to keep the discussion, development, and understanding of the issues moving forward. Wheel Rail Seminars has established an enviable record and standard for doing that.

Jeff Tuzik is Managing Editor of Interface Journal

This article is based on presentations made at multiple Wheel-Rail-Seminars conferences.

Featured image: Jack Lindquist