On-Board Top of Rail Friction Modifier Application: A More Efficient Approach?

By Jeff Tuzik

Friction modifiers—whether gage-face lubricants (greases) or top-of-rail (TOR) friction modifiers (FM)—are a well-established, and indeed, a common part of the wheel/rail optimization toolkit. In the railroader’s mind, these technologies tend to be associated with wayside application equipment and installations, but vehicle-mounted wheel-flange lubricators and wheel-tread friction modifiers have become increasingly common, as well.

Although TOR FM has typically been associated primarily with wayside solutions, new applicator technologies and FM consumables are providing railways with novel opportunities for implementing vehicle-based friction-management programs that can deliver equivalent or better performance than their wayside counterparts.

When it comes to gage-face and wheel-flange lubrication, the aims are straight-forward and intuitive: reducing the coefficient of friction to reduce wear. Of course, there are knock-on effects as well, such as reductions in noise, lateral forces, and wheel-climb potential.

Top-of-rail (TOR)/wheel-tread friction modification have different aims, and these tend to involve more complex or esoteric mechanics of wheel/rail interaction. Generally, the goals are to reduce lateral forces (and thus lower L/V ratios), the development of corrugation, RCF, TOR rail, and wheel-tread wear, and wheel/rail-related noise, and to improve wheelset steering and fuel efficiency. “Especially on transit systems, top-of-rail squealing noise in curves is of paramount concern, and a big reason for TOR [friction modifier] use,” said Marco Santoro, Manager of Global Friction Management Applications at L.B. Foster, speaking at the 2024 International Collaborative Research Initiative conference. But this is not an exhaustive list; TOR FM has historically been leveraged to address a wide range of wheel/rail interface concerns (see Total Friction Management on CPKC’s Thompson Subdivision and Beyond – Interface Journal and Developments in Top of Rail and Gage Face Friction Management Consumables – Interface Journal for more information).

“From a friction-management perspective, wayside application is a complex proposition; the amount of equipment and the maintenance required, the material carry-down rates, these are simply not as ideal as onboard solutions.” In other words, the ideal application method minimizes waste and the amount and complexity of associated equipment, simplifies and centralizes maintenance, and applies FM product directly where it’s needed. Of course, there is often a gulf between what is ideal and what is practical.

Early Days in Heavy Haul

On-board application of TOR FM initially focused on freight railroads. Class 1s have vast territories. Wayside equipment is often located in remote and difficult-to-access areas; maintenance personnel are often stretched thin. It’s a combination of factors that would seem to lend itself well to on-board rather than wayside FM application. L.B. Foster developed an on-board system that could be be installed on any car type, including locomotives. Pilot programs at BC Rail, Union Pacific, and Shuohuang Railroad/China Energy showed positive results, he said, in terms of L/V reductions, wear reduction, and fuel savings, Santoro said. (Results from studies of these programs were presented at the International Heavy Haul Association Conference (IHHA 2005, the Wheel/Rail Interaction Conference 2015, and IHHA 2023, respectively).

Shuohuang Railroad/China Energy has since adopted on-board TOR application on a large scale. But it’s important to note that this is a closed-loop/captive-fleet system. The economics and logistics of vehicle-based FM solutions are different in North America where freight cars operate in free interchange. Additionally, North American freight railways have already invested heavily in wayside lubrication and TOR FM units, so there is significant institutional momentum behind maintaining the existing wayside infrastructure and methodology, Santoro said. Hence, wayside application has remained dominant method of TOR FM in North America.

But rail transit presents a very different environment.

A Pivot to Transit

Years of data and experience from heavy-haul projects showing the benefits of onboard TOF FM led to the development of KELTRACK On-Board (KOB), a transit-specific version of this technology, which is paired with a water-based TOR friction modifier. Transit systems are particularly interested in on-board systems, in part, due to their notoriously tight maintenance windows—a piece of equipment that can be installed, maintained, and serviced in the shop, rather than requiring track access (as in the case of a wayside applicator), is appealing, Santoro said.

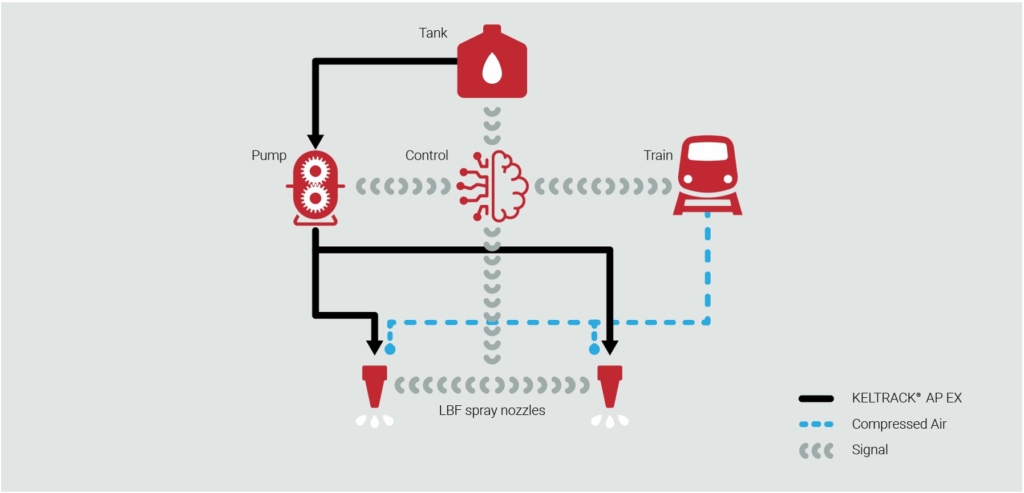

Another benefit to onboard systems is that they can selectively target where and when FM product is applied, rather than being tied to static wayside locations. “The [applicator] control unit can be adjusted for various conditions—ensuring that product isn’t applied during braking or sanding operations, or in specific sensitive areas,” Santoro said. “It can be applied only where it’s needed.” Because the FM product is precisely targeted, overall product use (or rather overuse) is easier to monitor and avoid. Settings and parameters can be pre-programmed and/or tied to a train’s own control unit and GPS systems. They can also be adjusted manually via an interface located in the cab. All told, this type of system provides a level of control granularity that isn’t available on wayside or older on-board-type applicators.

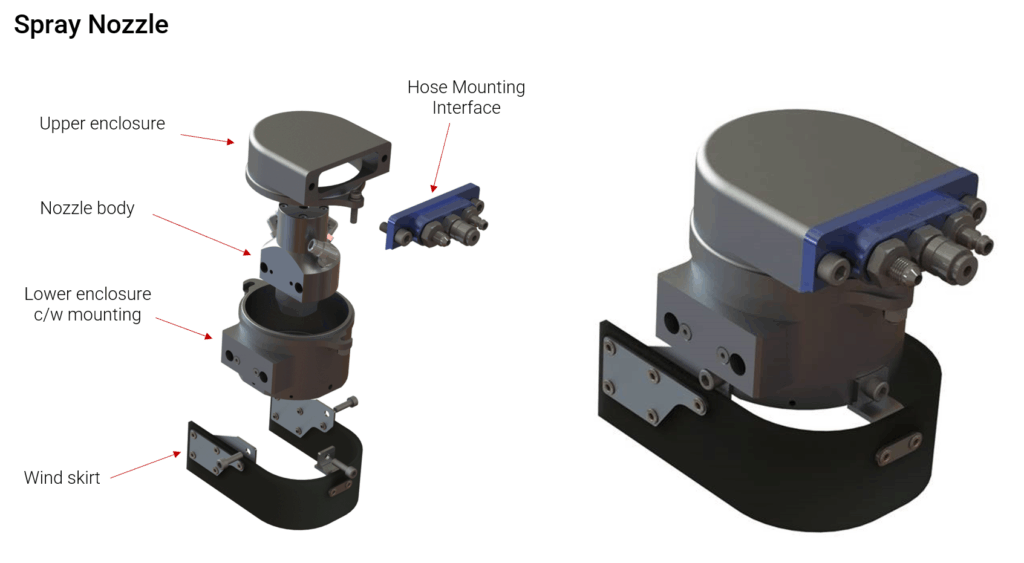

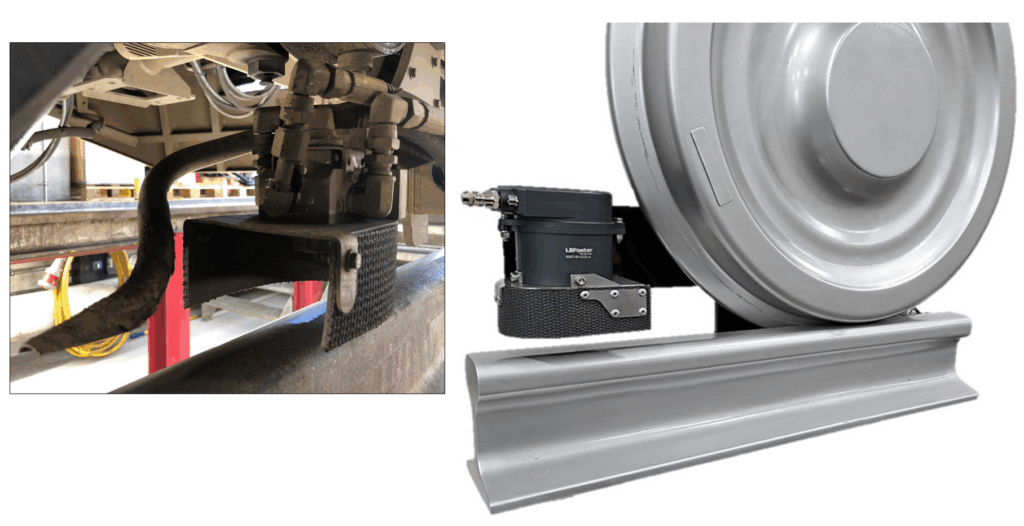

One of the challenges in designing an effective and reliable on-board applicator, Santoro said, is the design of the spray nozzle. The underside of a moving train is a very unforgiving environment; a spray nozzle must be precise yet rugged enough to withstand the rigors. “The nozzle has to atomize the [FM] product to produce a very fine mist. You don’t want a puddle on the rail that’s going waste product and lead to poor carry-down,” Santoro said. It’s also important to account for the speed of the vehicle itself—applying product on fast-moving train is effectively like spraying into the wind. The nozzle must be accurate and powerful enough to account for such conditions. Figure 1 shows an exploded view of the KOB spray nozzle. Figure 2 shows a mounting configuration for such units.

The Right Stuff

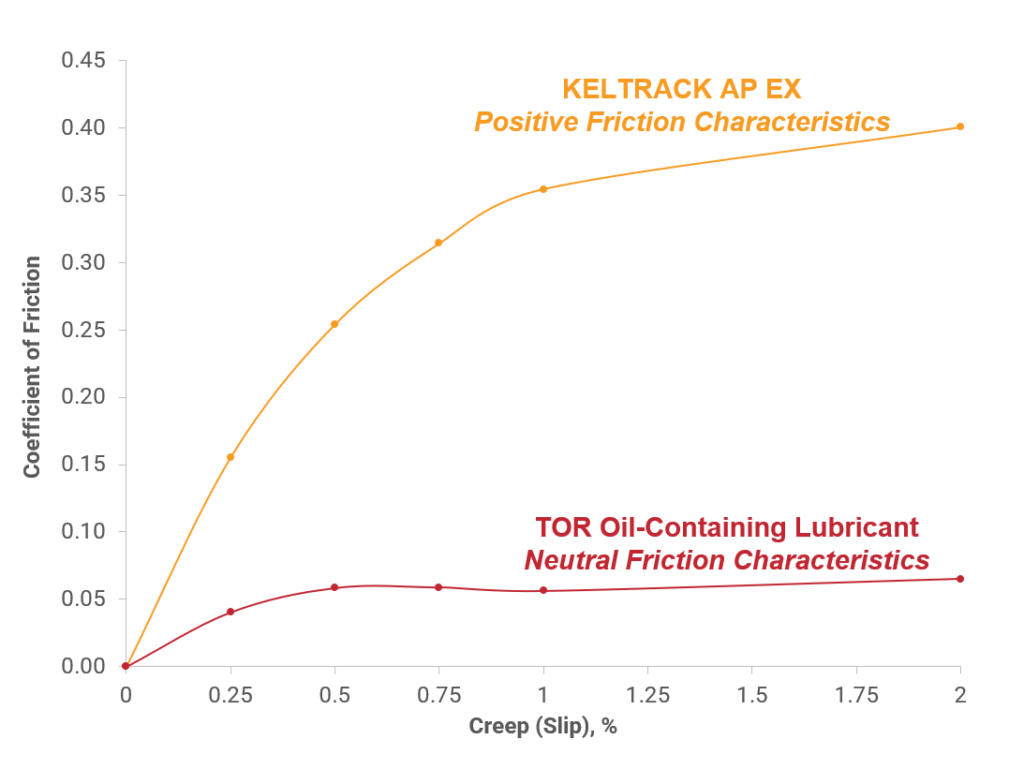

The FM product designed for use with the KOB applicator is a water-based product designed to maintain an intermediate coefficient of friction in the range of 0.30 to 0.40 — a fairly standard target for TOR FM products that balances the benefits of friction reduction with requirements for unencumbered traction and braking capability. Figure 3 shows data from twin disc testing; the red line indicates the performance of the TOR product used in the KOB system.

Figure 4 shows data measuring COF under creep (or slip) conditions from testing on twin-disc equipment. Note that for oil-based, lubricant-type products, the COF remains fairly constant (and low) regardless of creep/slip values. Friction modifiers designed to maintain an intermediate COF, on the other hand, tend to increase their COF value as creep/slip increases, Santoro said. From a practical standpoint, this is important in minimizing stick-slip (and its attendant damage to the wheel and rail) at the wheel/rail interface when a wheel is under traction. “Stick-slip is a key contributor to damage like corrugation, but it has a big effect on wheel/rail squeal noise, as well,” he said.

It’s also important to note that on-board systems do not require TOR FM product to be applied by each train, on every pass. “The sweet spot is generally for every fifth to tenth train to apply the product,” Santoro said. The engineered-in retentivity of the product applies benefits to all trains in between the applications.

A Body of Research

Data collected from various lab and field studies1 have catalogued the efficacy of water-based FM on-board application regimes (compared to dry/untreated rail) and found them to be capable, under ideal conditions, of reducing lateral forces by up to 59% (vastly improving L/V ratios) and mitigating or eliminating corrugation development altogether.

Another study2, this one focused on the effect of TOR FM on the development of short-wave corrugation found that even on different types of transit systems (an EU metro, and EU commuter line, and two Japanese metros) the use of TOR FM reduced the rate of corrugation growth by 87% to 91% (depending on the system and the specific track section).

Other studies have examined the effects of on-board TOR FM on wheel, rather than rail, condition3. One such study conducted by Union Pacific focused on premature wheel condemnation due to tread damage—primarily RCF and shelling/spalling. “Their data showed that two-thirds of the wheels they were replacing was due to heavy RCF on the tread,” Santoro said. The study compared WILD data and wheel-wear-rate data pre- and post-TOR FM implementation and found promising results; the FM program led to a ≈60% reduction in >90-kip wheel impacts, and a ≈50% reduction in average wheel wear rate.

This is only a sampling of such studies, but there is a robust body of evidence supporting the primary and ancillary benefits of well-implemented TOR FM regimes. Not all these benefits are intrinsic to on-board FM systems, but many of the studies did single out this application method, specifically.

On-board application can streamline friction management programs and eliminate many of the logistical complexities associated with wayside technologies, track access, and maintenance personnel exposure, Santoro said. Years of studies appear to bear this out. It remains to be seen whether on-board TOR FM application systems will gain greater acceptance and adoption in the North American and the global transit environment. But a case for it is taking shape.

- 2004-03-01_Y. Suda. Development of Onboard Friction Control

University of Tokyo, Tokyo Subway (TRTA), Sumitomo Metal

Journal Wear 258 (2005) 1109-1114 ↩︎ - 2006-09-24_D. Eadie. Field Studies on the Effect of FM on Short Pitch Corrugation

L.B. Foster, Sumitomo Metal

7th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems (CM2006), Brisbane, Australia, September 24-26, 2006 ↩︎ - 2015_J. Peters. The Effect of Train Mounted TOR-FM on Wheel Life and Defects

Union Pacific Railroad, L.B. Foster

Wheel Rail Interface Conference 2015 ↩︎

Jeff Tuzik is Managing Editor of Interface Journal.

This article is based on a presentation made at the 2024 International Collaborative Research Initiative Conference.

All images are courtesy of L.B. Foster.