Currently browsing category

Measurement Systems

Friction Management: Implementation and State of Good Repair

Friction management is a crucial aspect of rail transit, improving wheel/rail interactions by reducing wear, noise, and safety risks. Effective implementation involves tailored strategies based on specific issues. Successful transit agencies employ proper asset management, ensuring consistent results and a strong return on investment through maintenance and optimized practices.

Mitigating Transverse Defects and Reducing Non-testable Areas: Grinding Strategies at CSX

Transverse defects (TDs) pose significant challenges for freight railroads, causing 31% of broken rails. CSX has enhanced its rail grinding program since 2016, reducing non-testable locations by 98% and TD occurrences by 37%. Effective grinding mitigates the risks of TDs, improves ultrasonic detection, and balances defect removal with rail profile maintenance.

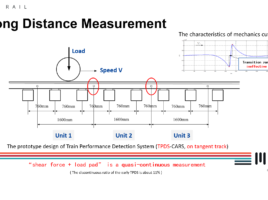

New Approaches to Dynamic Wheel Force Measurement – Part 2

The article discusses advancements in wheel condition monitoring technologies, particularly by Mermec and MxV Rail. Various methods, including optical and strain gauge systems, gather data on dynamic forces and out-of-roundness. Enhanced systems promise improved predictions of hunting behavior and overall wheel integrity, increasingly complementing traditional inspection techniques in railways.

New Approaches to Dynamic Wheel Force Measurement – Part 1

The article discusses the significance of wheel/rail interaction in railroading, emphasizing the importance of both wheels and tracks. Advances in monitoring technologies, such as continuous wheel condition monitoring and load detectors, enhance safety and maintenance. It highlights challenges and improvements in measuring forces effectively, contributing to efficient railroad operations.

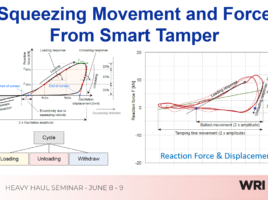

Smart Rocks, Smart Tamper: Investigating the Mechanics of Ballast Tamping

by Jeff Tuzik There are many forces that work to deteriorate track geometry over time. These forces don’t begin and end at the wheel/rail interface, they are transmitted to the vehicles and their components, and into the track structure and its components. On ballasted track, ballast absorbs these forces; and …

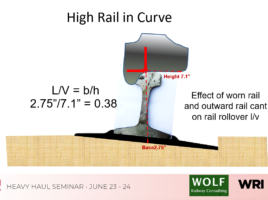

Using Derailment Findings to Identify Derailment Risks

Presenters at the 2022 Wheel/Rail Interaction conference looked at heat and track configuration issues as they relate to derailment potential in heavy-grade, high-tonnage territory. They also looked at the role of Operating parameters in derailment potential, and at the findings from 20 years of investigations into derailments. By Bob Tuzik …

Examining Autonomous Track Geometry Testing and Instrumented Revenue Vehicle Technology

A pair of speakers from different continents discuss the benefits of autonomous track geometry collection and the advantages of monitoring revenue-service vehicles’ response to track conditions in this first installment of topics covered at this year’s annual Wheel/Rail Interaction Conference in Vancouver, B.C., Canada. By Bob Tuzik Brad Kerchof wasted …

Moving to Performance-Based Automated Track Inspection: The Benefits and Hurdles Ahead

By David C. Lester The mileage of individual Class 1 railroad networks presents a challenge to inspectors and engineers to inspect frequently enough to keep the track in good shape and minimize the frequency of track-related derailments. Traditional inspections done by railbound geometry cars and flexible hi-rail trucks, with the …

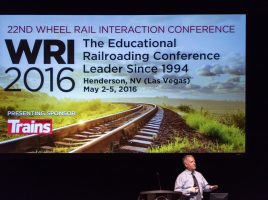

WRI 2016 – Transit: Integration, Correlation, Remediation

By Jeff Tuzik It’s easier now than ever to collect data on wheel/rail interaction. The number of measurement tools, the number of parameters that can be measured, and the accuracy of those measurements have changed the way wheel and rail systems are designed, monitored and maintained. While all of …