Vehicle/Track Interaction from a Car Design Perspective

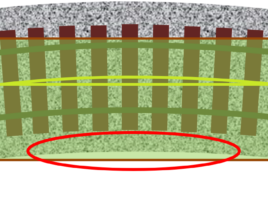

Jonathan Sunde from Strato, Inc. emphasized at the Wheel Rail Seminars that wheel/rail dynamics are critically influenced by car and coupler designs. As curves become sharper, swingout distances increase, affecting clearance and coupling performance. The AAR standards guide design choices to minimize risks of buff and draft failures, ensuring safe operations in diverse freight conditions.