How Sound Transit Controls Train-Borne Noise

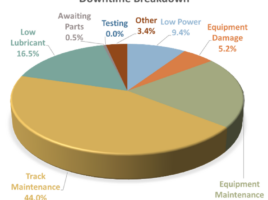

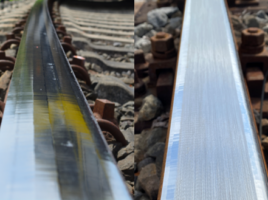

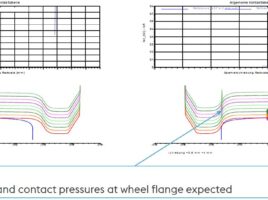

by Bob Tuzik This article was originally published in Mass Transit (June 2023). Challenges abound in the design, construction, maintenance, and operation of light rail lines in urban areas. Chief among them is controlling track- and vehicle-born noise, an important part of maintaining the support of an agency’s various stakeholders, …