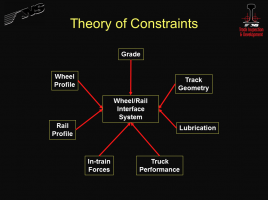

WRI 2014 Transit: A Systems Approach to Wheel/Rail Interaction

by Jeff Tuzik The 20th annual Wheel/Rail Interaction Conference drew a record number of attendees and speakers from around the world. They came to contribute to and draw from the growing body of knowledge on wheel/rail interaction. Since the conference began 20 years ago, the industry has come a …