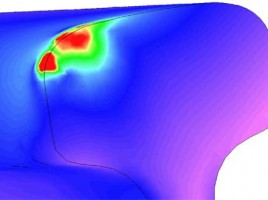

Understanding the Effects of Track Gauge, Wheel/Rail Geometry and Friction on Stresses at the Wheel/Rail Interface

By Jude Igwemezie, Ph.D., P.Eng. Over the years, rail grinding has become more the norm than the exception as the rail industry has recognized that damaged materials on the rail and wheel contact surfaces must be addressed before they become a bigger problem. The art of rail grinding has also progressed …