Moving to Performance-Based Automated Track Inspection: The Benefits and Hurdles Ahead

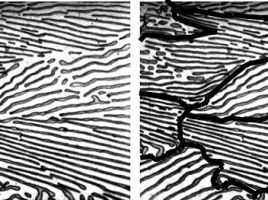

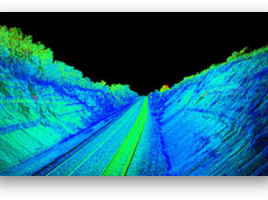

By David C. Lester The mileage of individual Class 1 railroad networks presents a challenge to inspectors and engineers to inspect frequently enough to keep the track in good shape and minimize the frequency of track-related derailments. Traditional inspections done by railbound geometry cars and flexible hi-rail trucks, with the …