Reducing the Stress State on Canadian Pacific’s Western Corridor

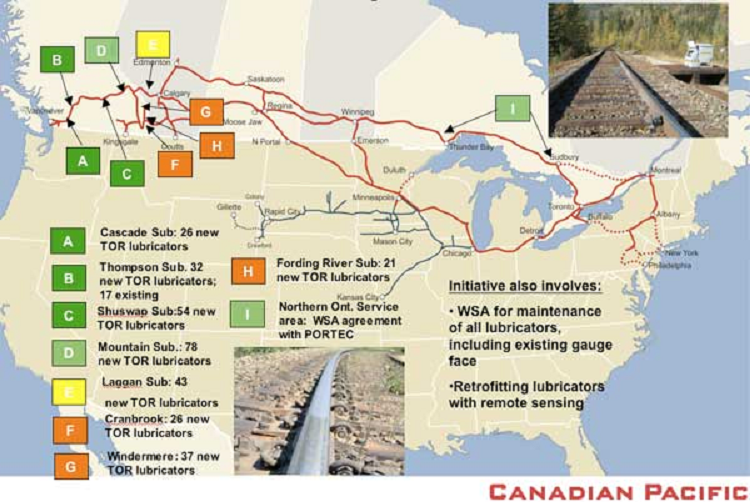

By Mike Roney • July, 2009 Canadian Pacific has taken a unique approach to reducing the stress state in its western corridor. The approach includes the implementation of distributed power and the implementation of friction management. It also includes examination of their combined effects — something that is relatively new. Looking at …