Designing Amtrak’s Wayside Train/Track Interaction Detection System

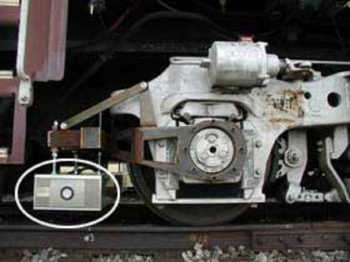

by Bob Tuzik, December 1, 2004 As part of its effort to monitor dynamic vehicle/track interaction on the Northeast Corridor, Amtrak commissioned ENSCO, Inc., to develop a Wayside Train/Track Interaction Detection System. The goal was to measure and collect information on vehicle/track forces that would enable Amtrak to determine the causes of …