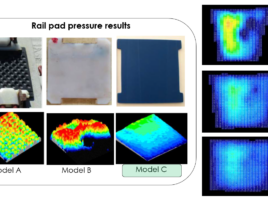

Using Elastic Components to Improve Rail, Tie, and Ballast Life

by Jeff Tuzik Track condition is about more than rails and ties. It includes everything below the rail and ties, too. Track components, ballast, and subgrade are all part of the package; they all affect overall track condition. And, as Brazil’s MRS Logistica’s track renewal programs have shown, improving track …