Derailment Mitigation at Switches and Turnouts: Three Perspectives

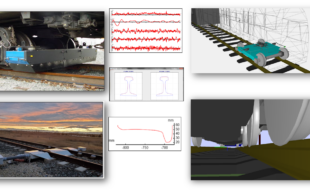

by Jeff Tuzik A lot of derailments happen at switches and turnouts. Many are low-speed, low-energy derailments that happen in yards and sidings. But they’re still costly and disruptive. Evaluating and optimizing wheel/rail contact conditions at these locations is different than it is on open track. It requires specific tools, …